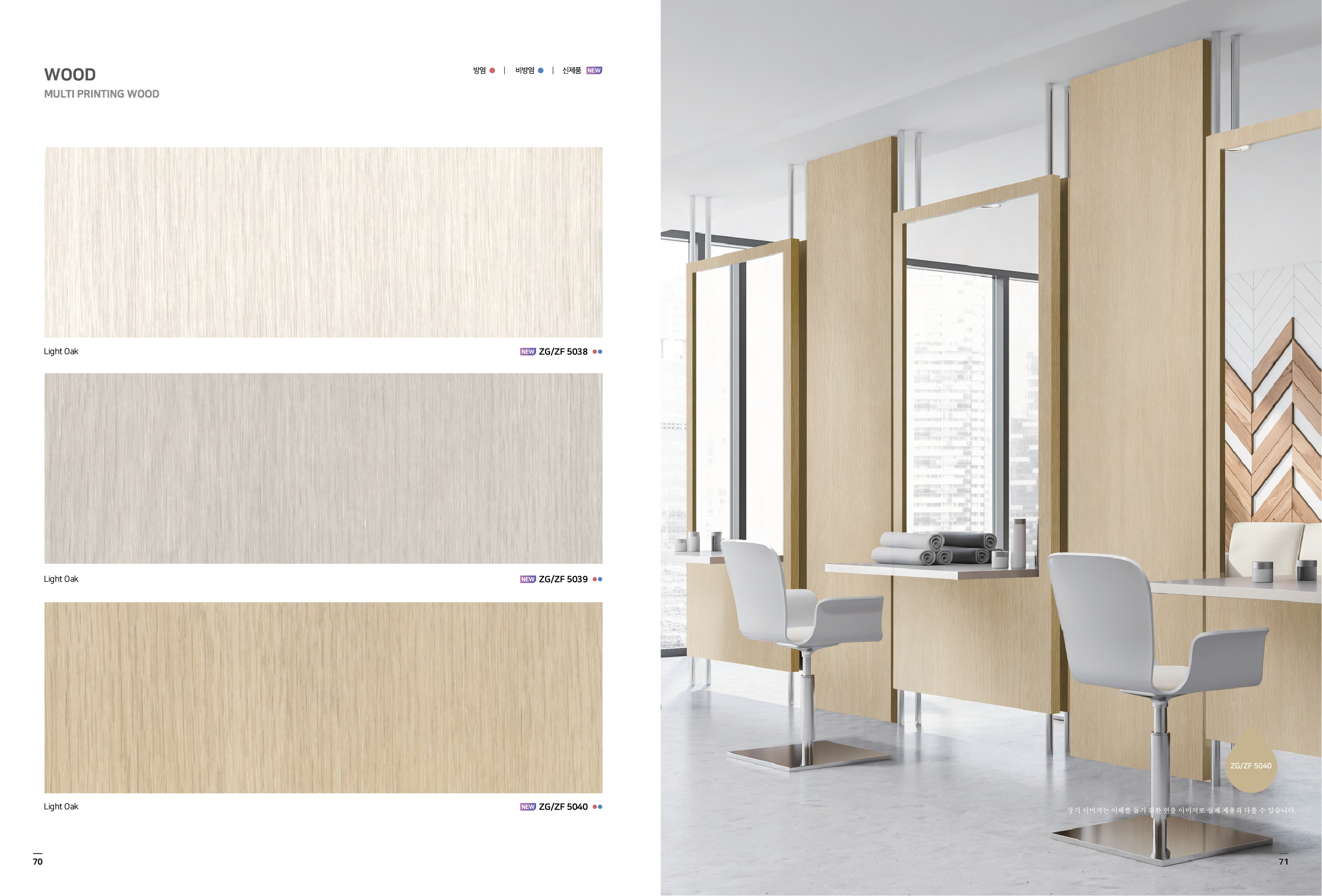

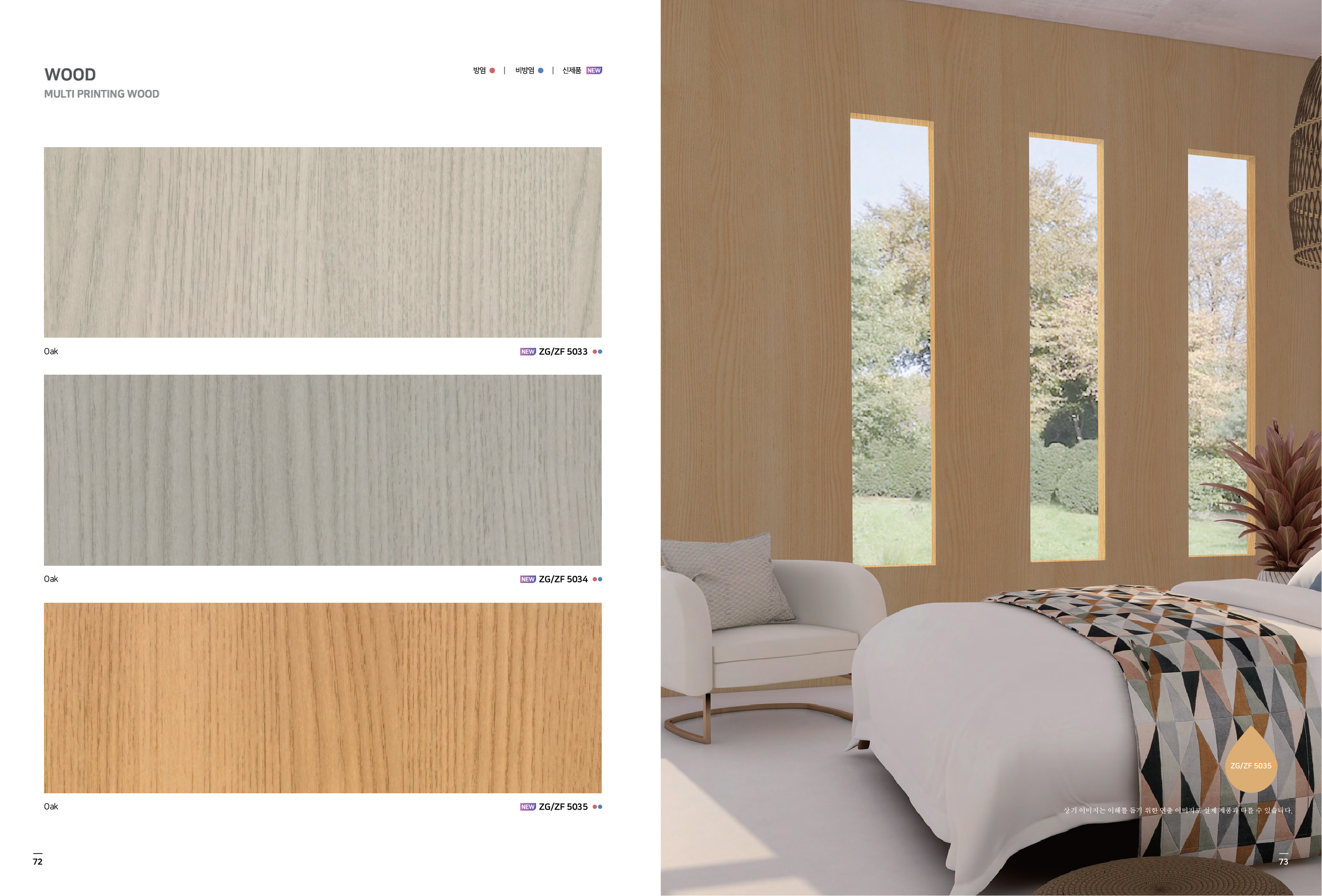

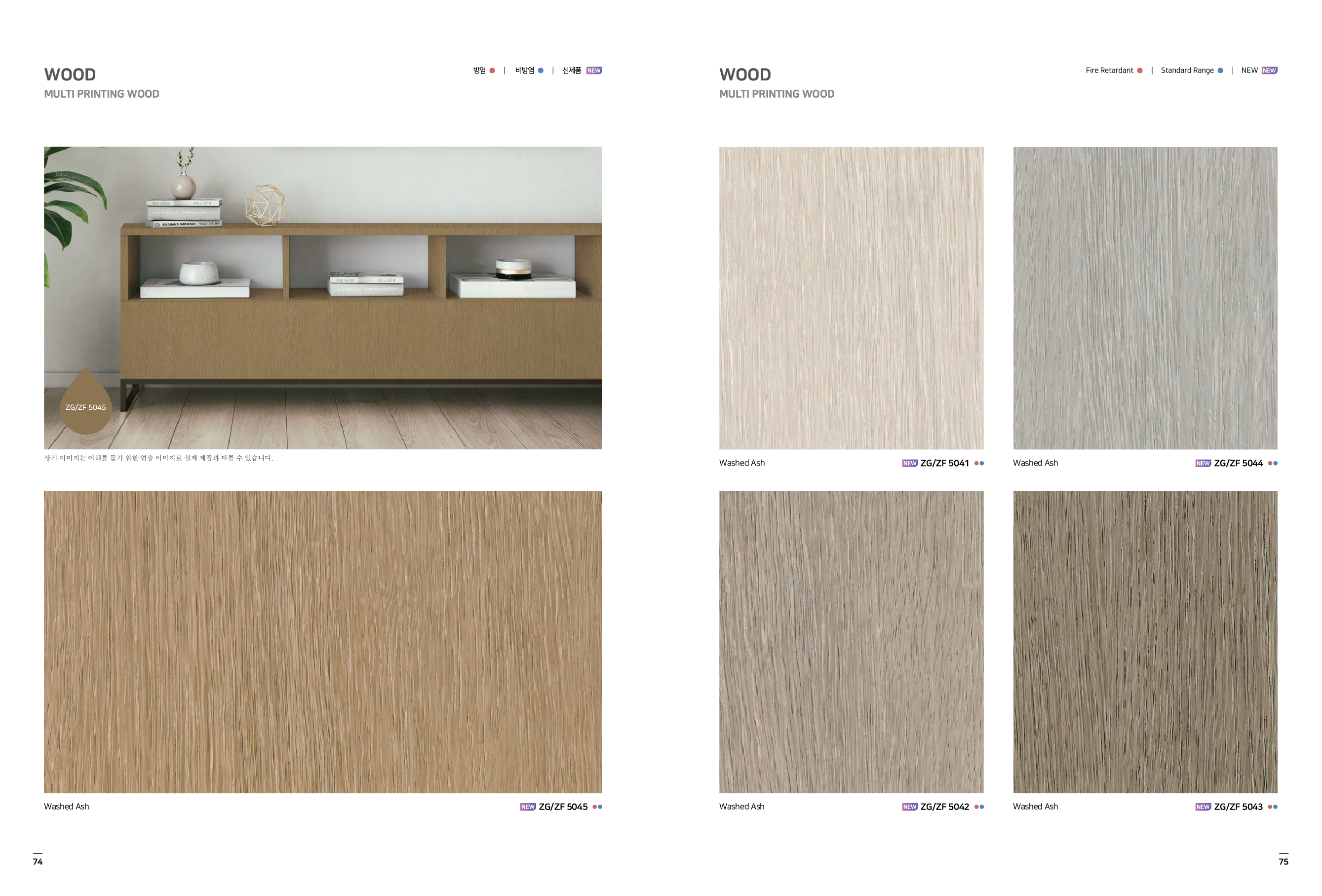

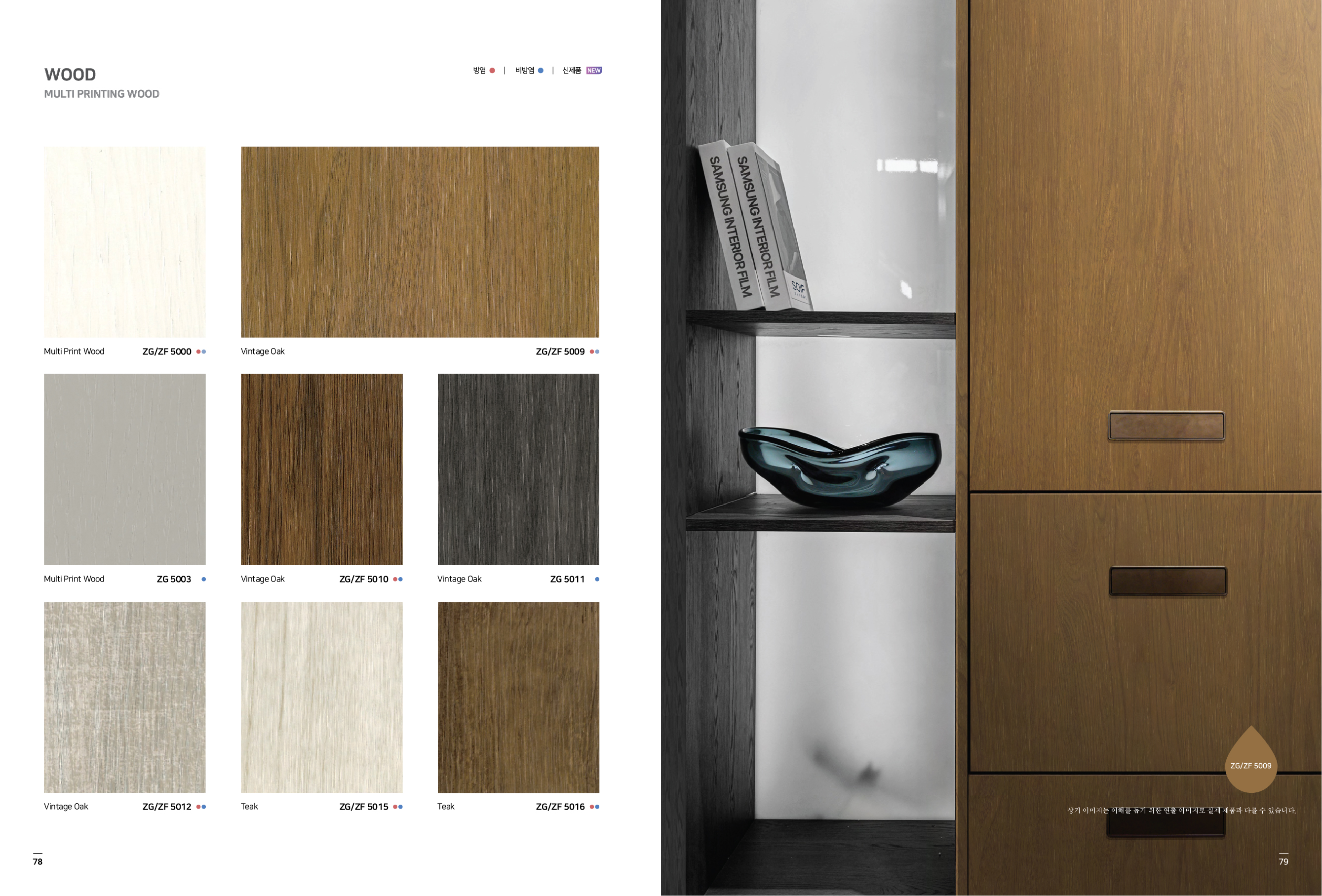

Catalog

Gallery

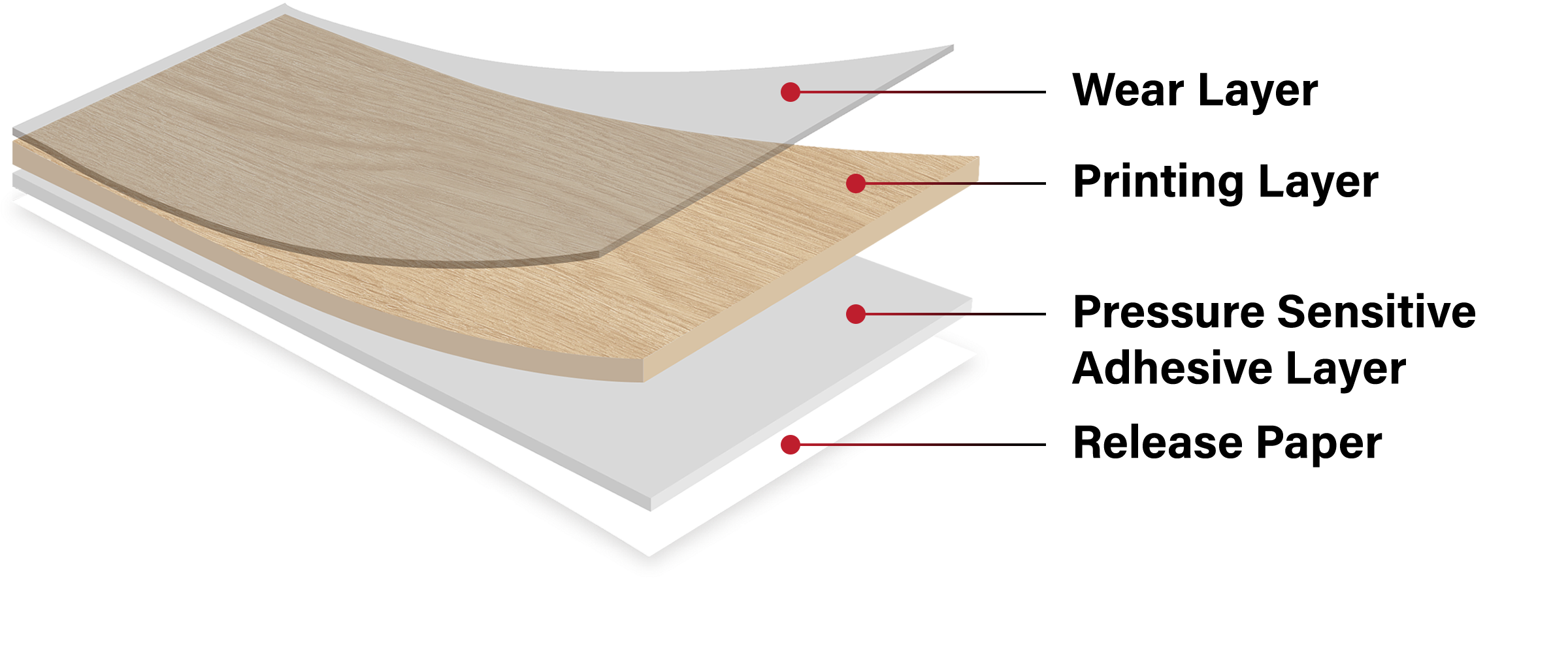

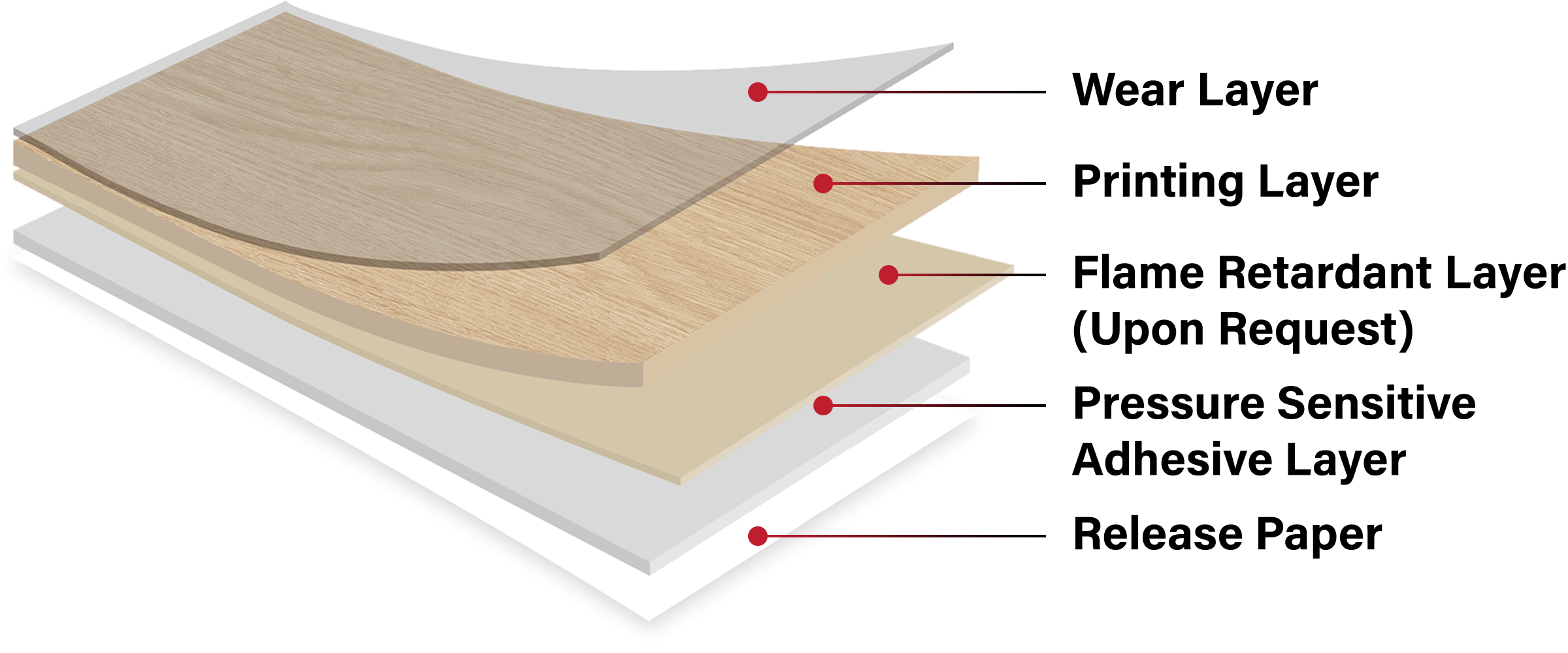

Product Structure

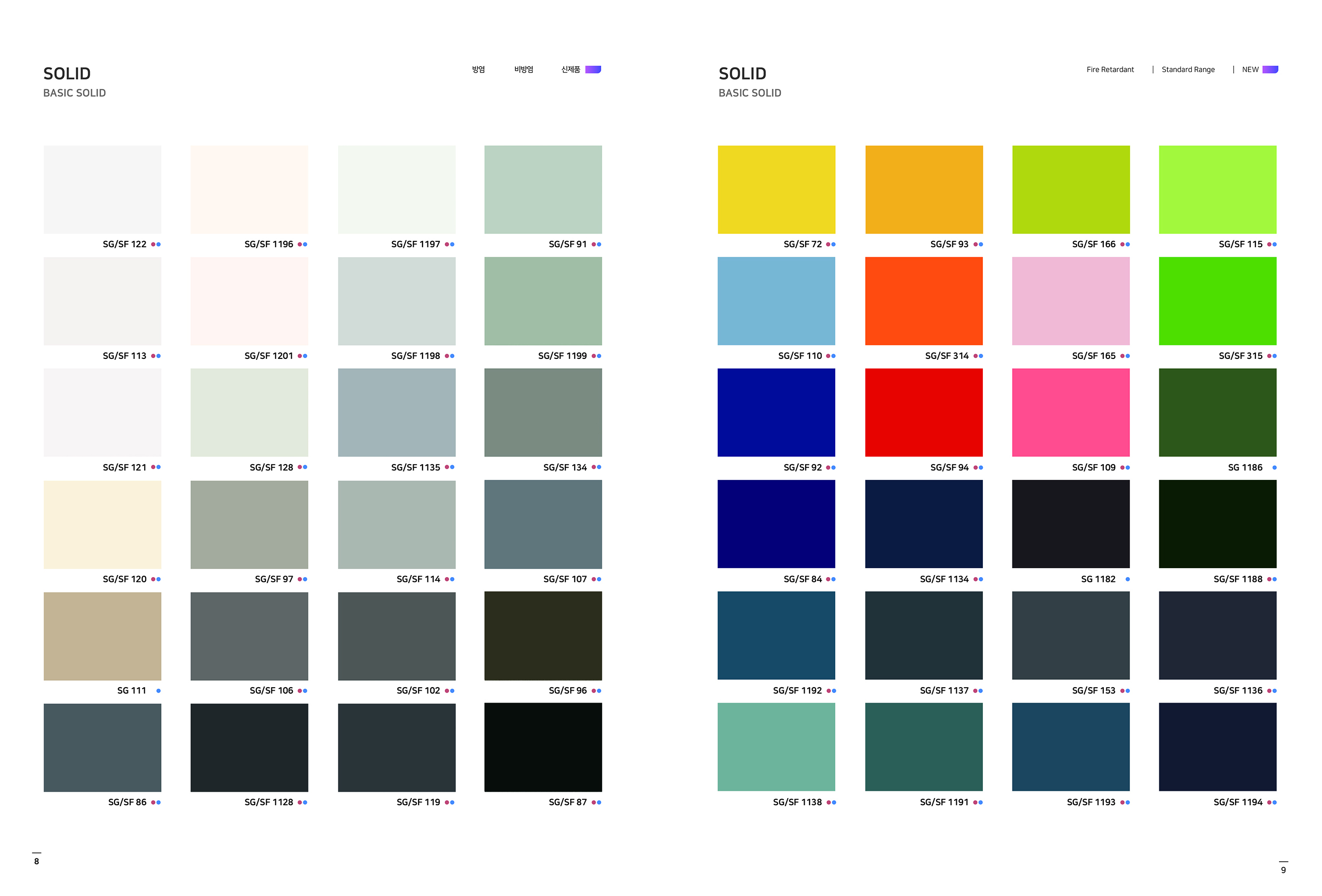

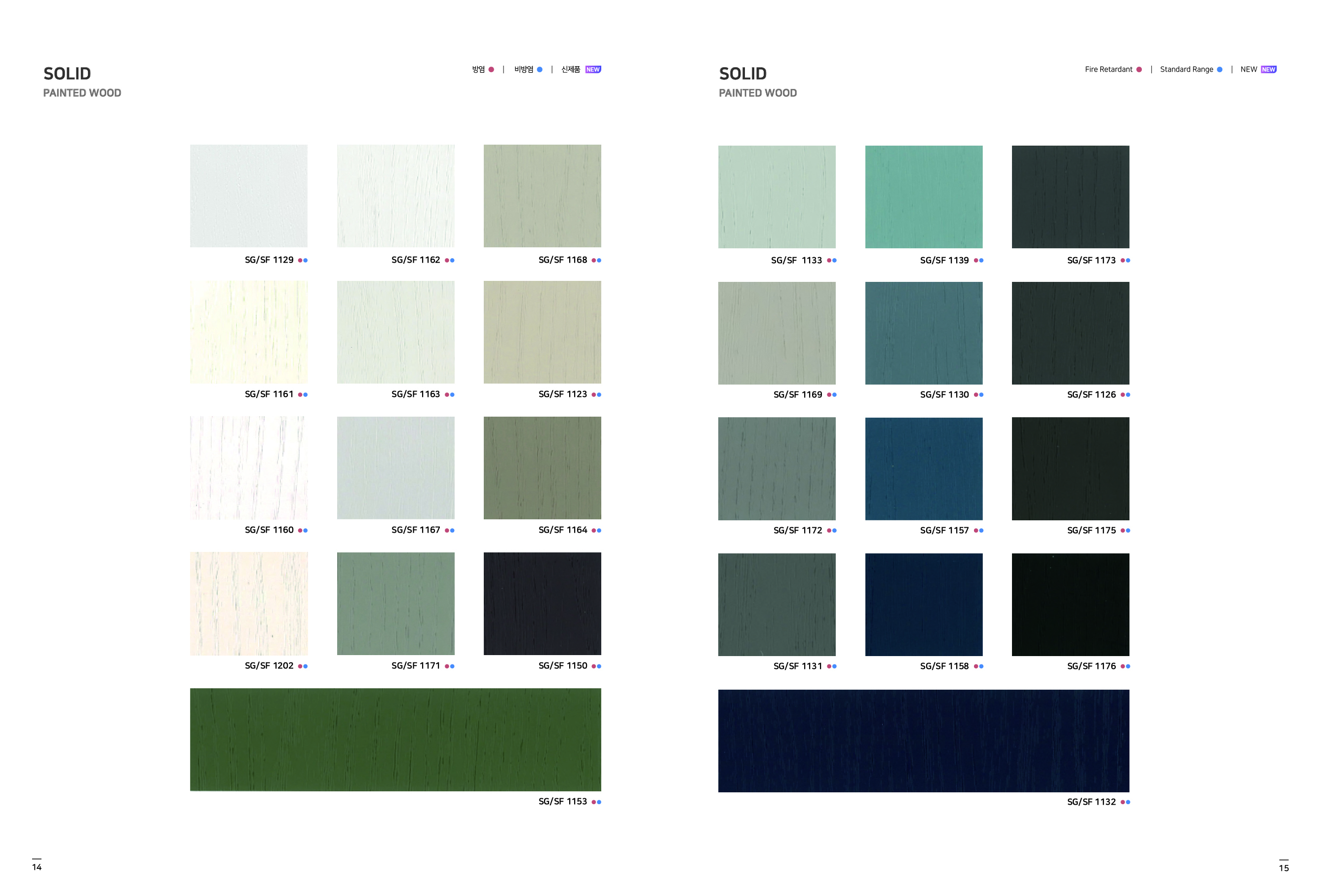

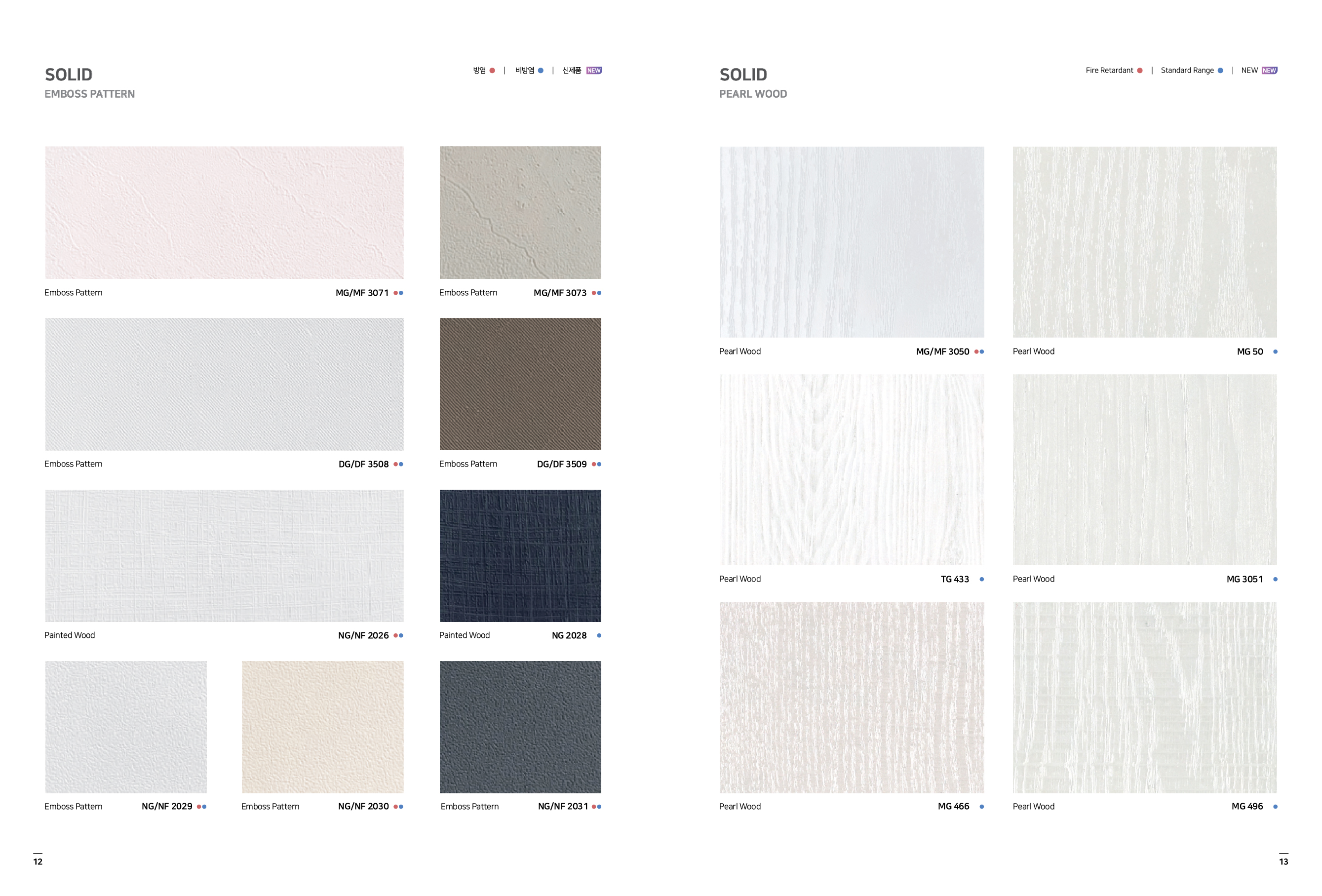

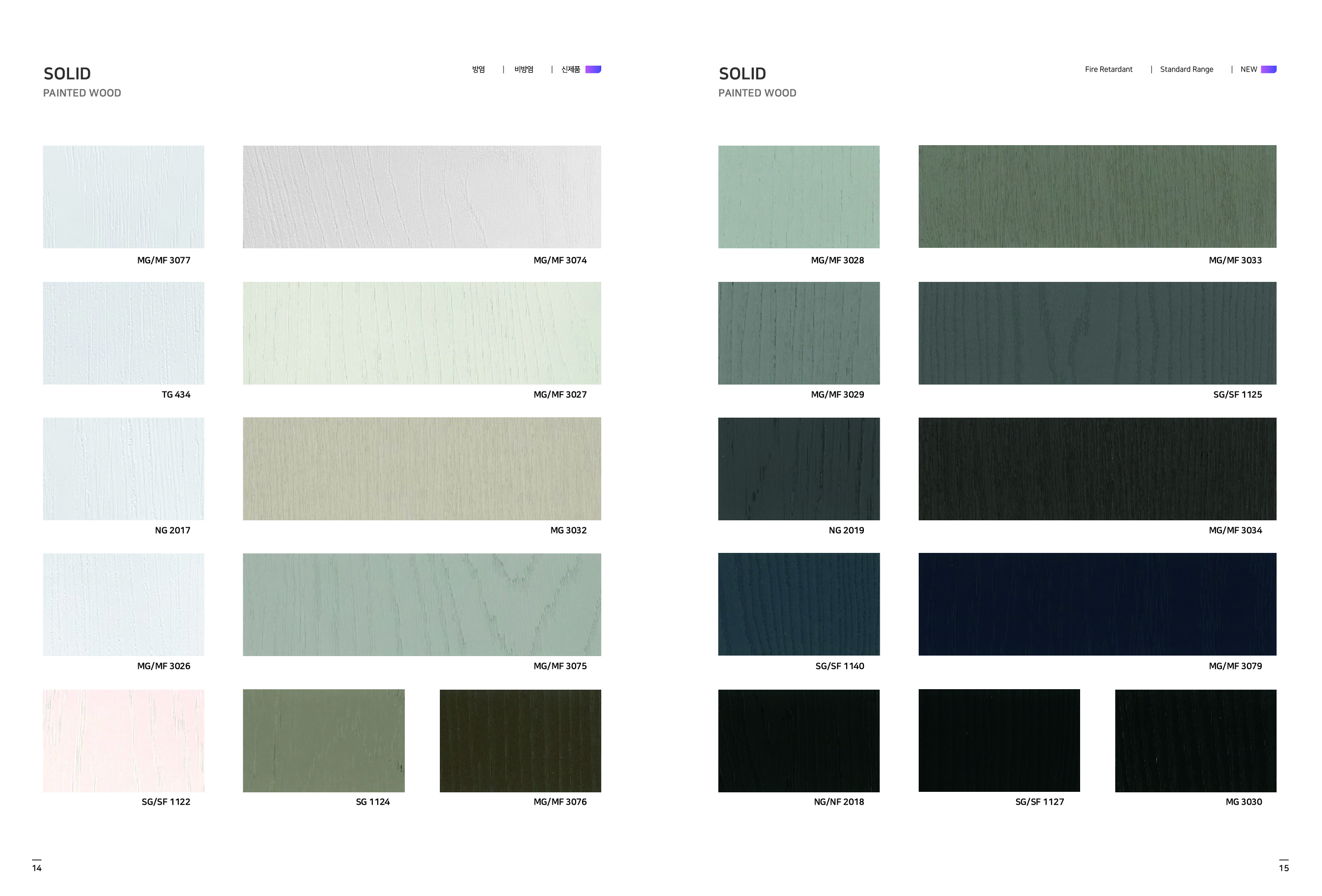

As a product that has excellent durability and has optained the highest grade of environmental mark and eco-friendly construction material, no heavy metals harmful to the human body are detected, and flame retardant products delay the spreading time of fire in case of fire and suppress the generation of toxic gases.

It is a proven building material that replaces the areas of pattern wood, paint, and wallpaper for the base in the field of new construction and remodeling.

Standard

Flame Retardant

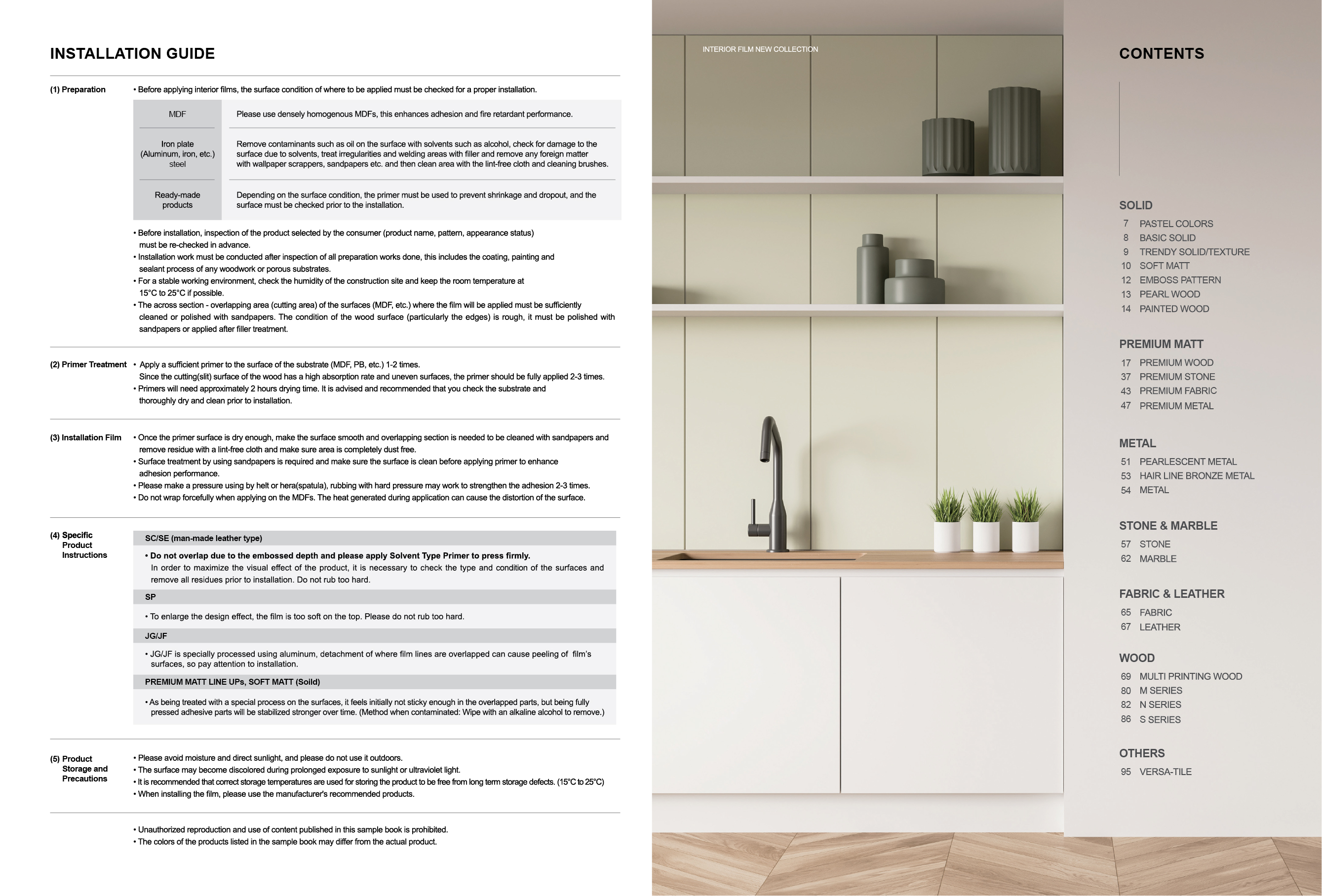

Installation Guide

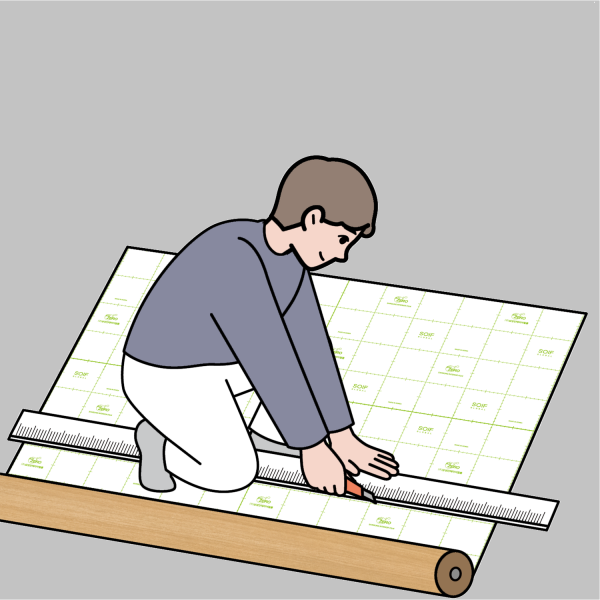

1. Preparation

-

Before applying interior films, the surface condition of where to be applied must be checked for a proper installation.

MDF Please use densely homogenous MDFs, this enhances adhesion and fire retardant performance. Iron plate (Aluminum, iron, etc.) steel Remove contaminants such as oil on the surface with solvents such as alcohol, check for damage to the surface due to solvents, treat irregularities and welding areas with filler and remove any foreign matter with wallpaper scrappers, sandpapers etc. and then clean area with the lint-free cloth and cleaning brushes. Ready-made products Depending on the surface condition, the primer must be used to prevent shrinkage and dropout, and the surface must be checked prior to the installation. - Before installation, inspection of the product selected by the consumer (product name, pattern, appearance status) must be re-checked in advance.

- Installation work must be conducted after inspection of all preparation works done, this includes the coating, painting and sealant process of any wood work or porous substrates.

- For a stable working environment, check the humidity of the construction site and keep the room temperature at 15°C to 25°C if possible.

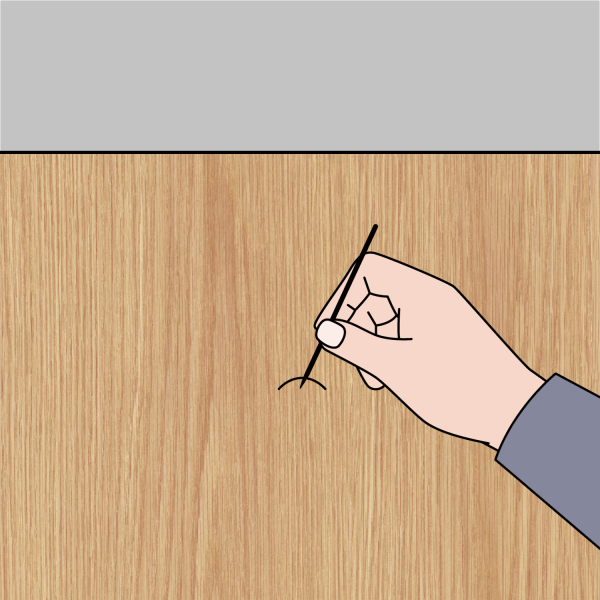

- The across section - overlapping area (cutting area) of the surfaces (MDF, etc.) where the film will be applied must be sufficiently cleaned or polished with sandpapers. The condition of the wood surface (particularly the edges) is rough, it must be polished with sandpapers or applied after filler treatment.

2. Primer Treatment

-

Apply a sufficient primer to the surface of the substrate (MDF, PB, etc.) 1-2 times.

Since the cutting(slit) surface of the wood has a high absorption rate and uneven surfaces, the primer should be fully applied 2-3 times. -

Primers will need approximately 2 hours drying time.

It is advised and recommended that you check the substrate and thoroughly dry and clean prior to installation.

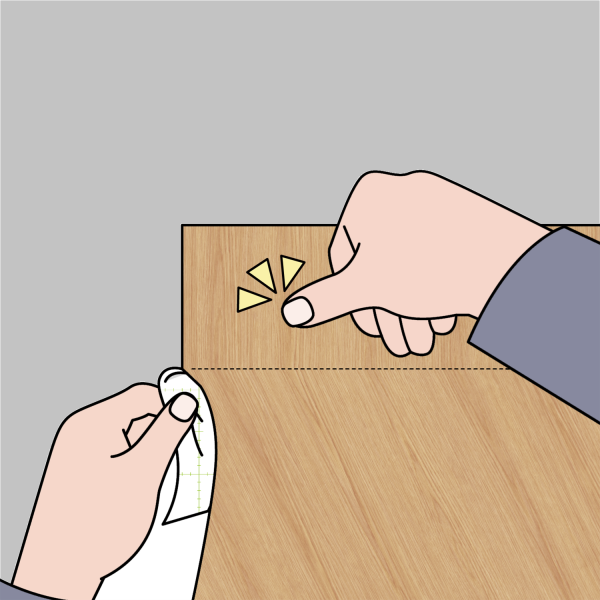

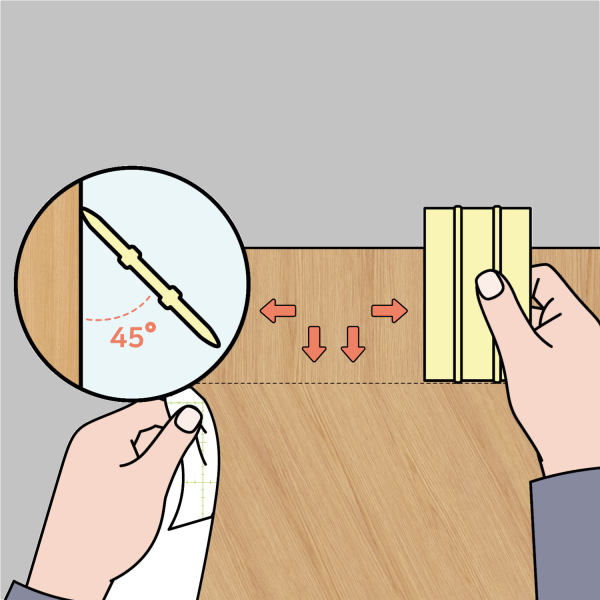

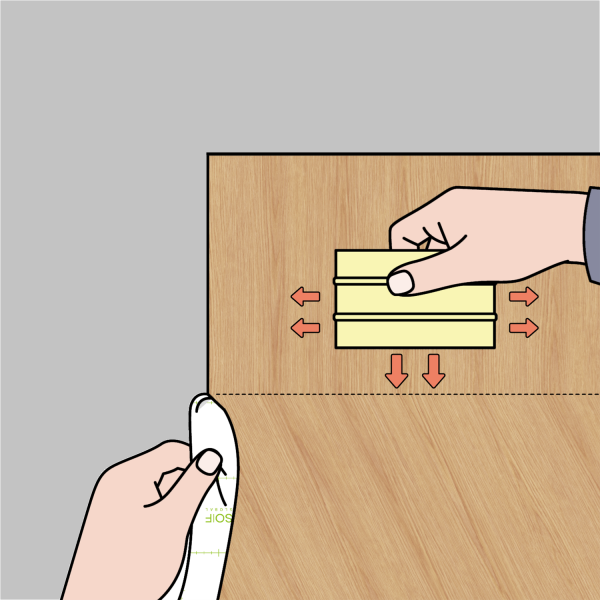

3. Installation Film

- Once the primer surface is dry enough, make the surface smooth and overlapping section is needed to be cleaned with sandpapers and remove residue with a lint-free cloth and make sure area is completely dust free.

- Surface treatment by using sandpapers is required and make sure the surface is clean before applying primer to enhance adhesion performance.

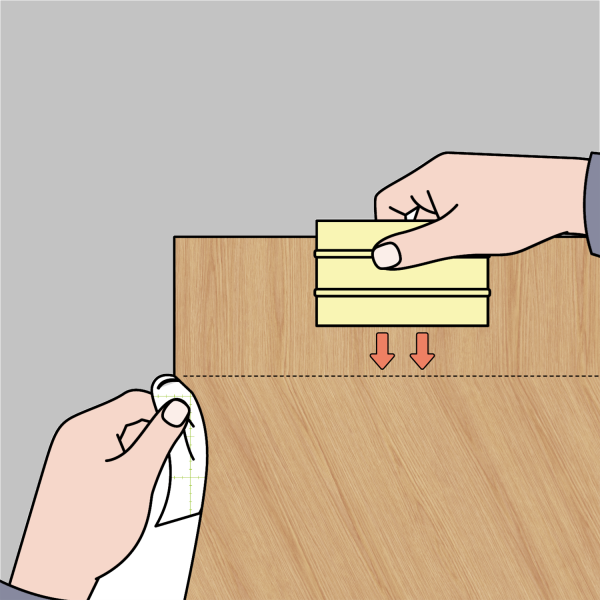

- Please make a pressure using by helt or hera(spatula), rubbing with hard pressure may work to strengthen the adhesion 2-3 times.

- Do not wrap forcefully when applying on the MDFs. The heat generated during application can cause the distortion of the surface.

4. Specific Product Instructions

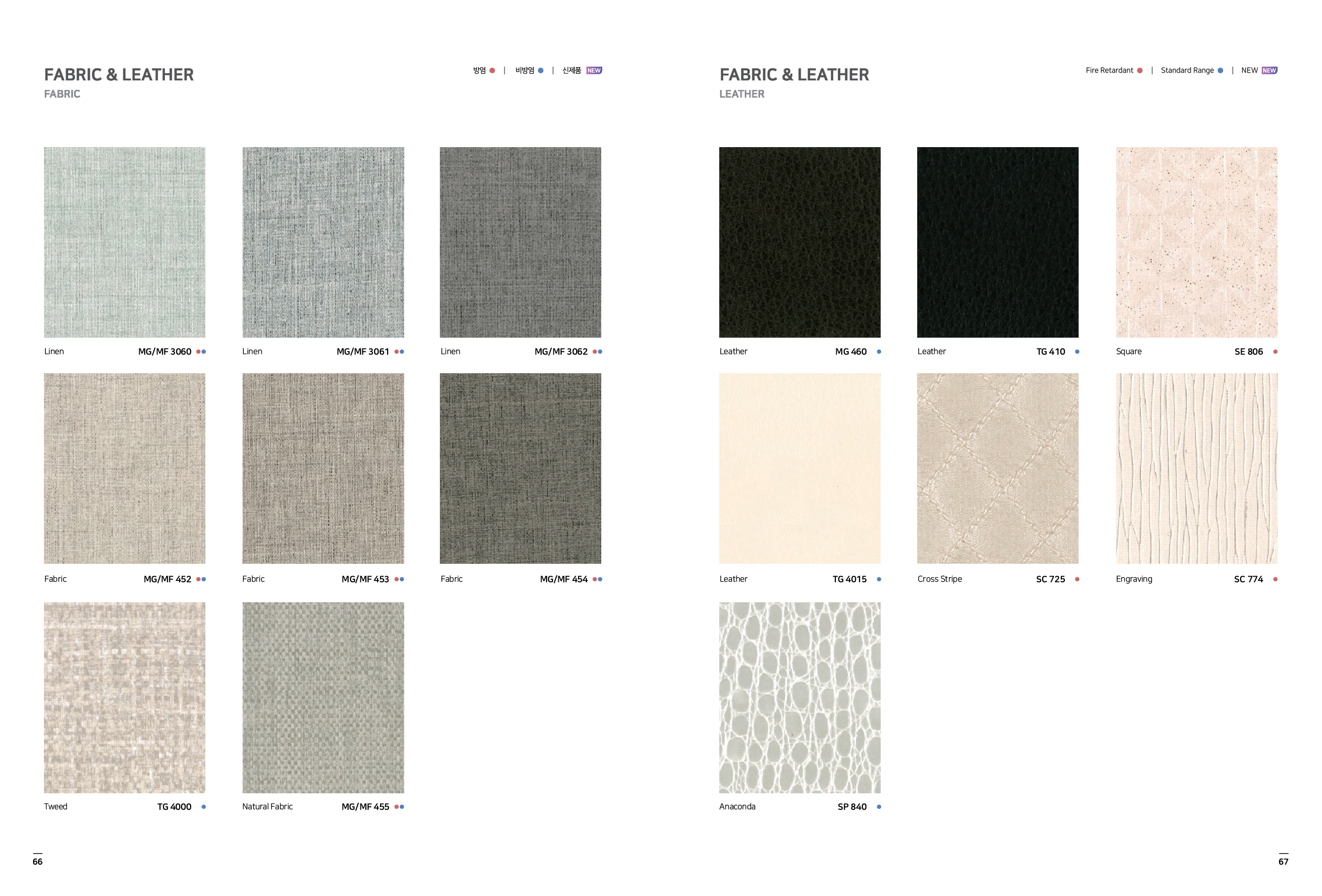

| SC/SE (man-made leather type) |

Do not overlap due to the embossed depth and please apply Solvent Type Primer to press firmly.

In order to maximize the visual effect of the product, it is necessary to check the type and condition of the surfaces and remove all residues prior to installation. Do not rub too hard. |

|

|---|---|---|

| SP | To enlarge the design effect, the film is too soft on the top. Please do not rub too hard. | |

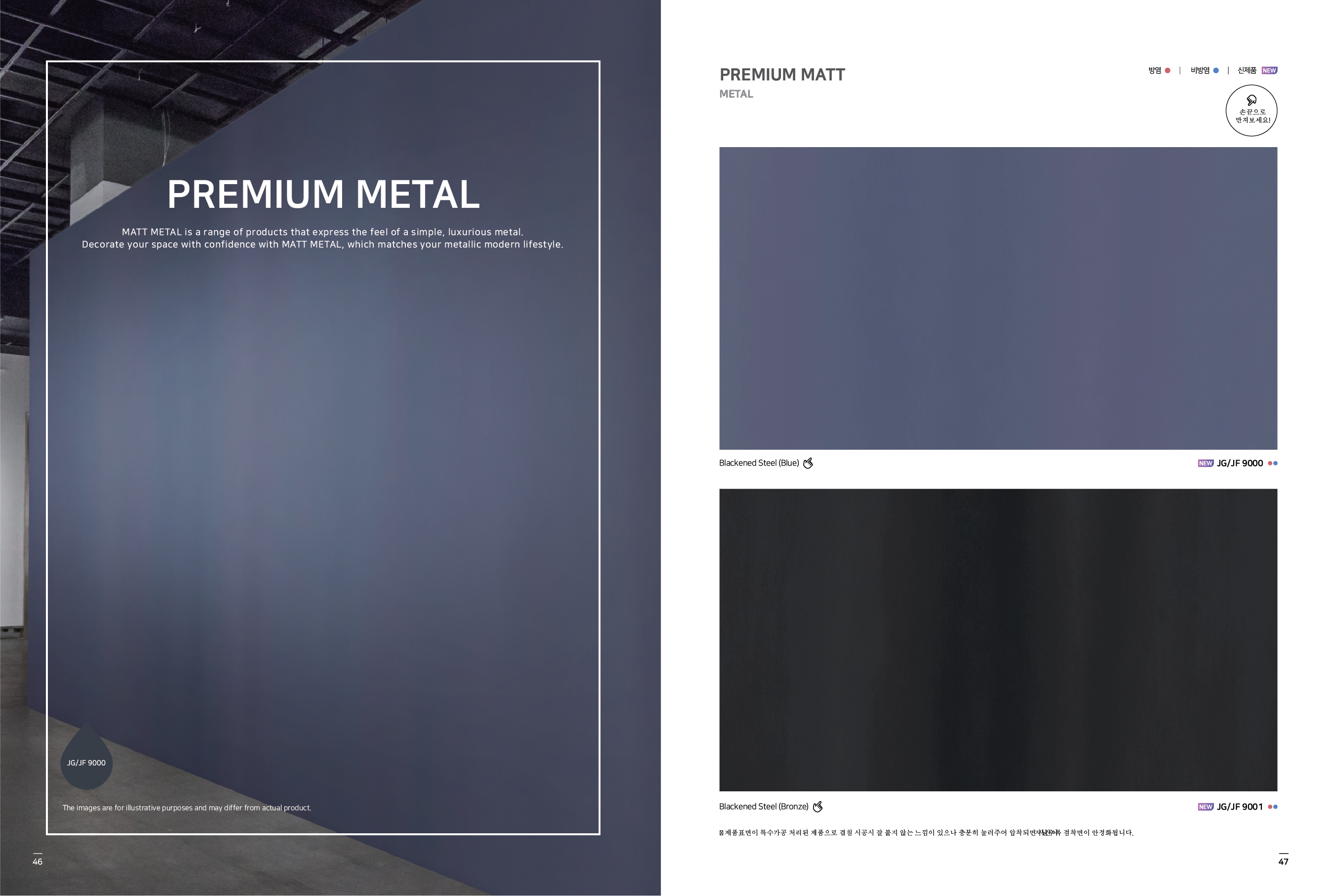

| JG/JF | JG/JF is specially processed using aluminum, detachment of where film lines are overlapped can cause peeling of film’s surfaces, so pay attention to installation. | |

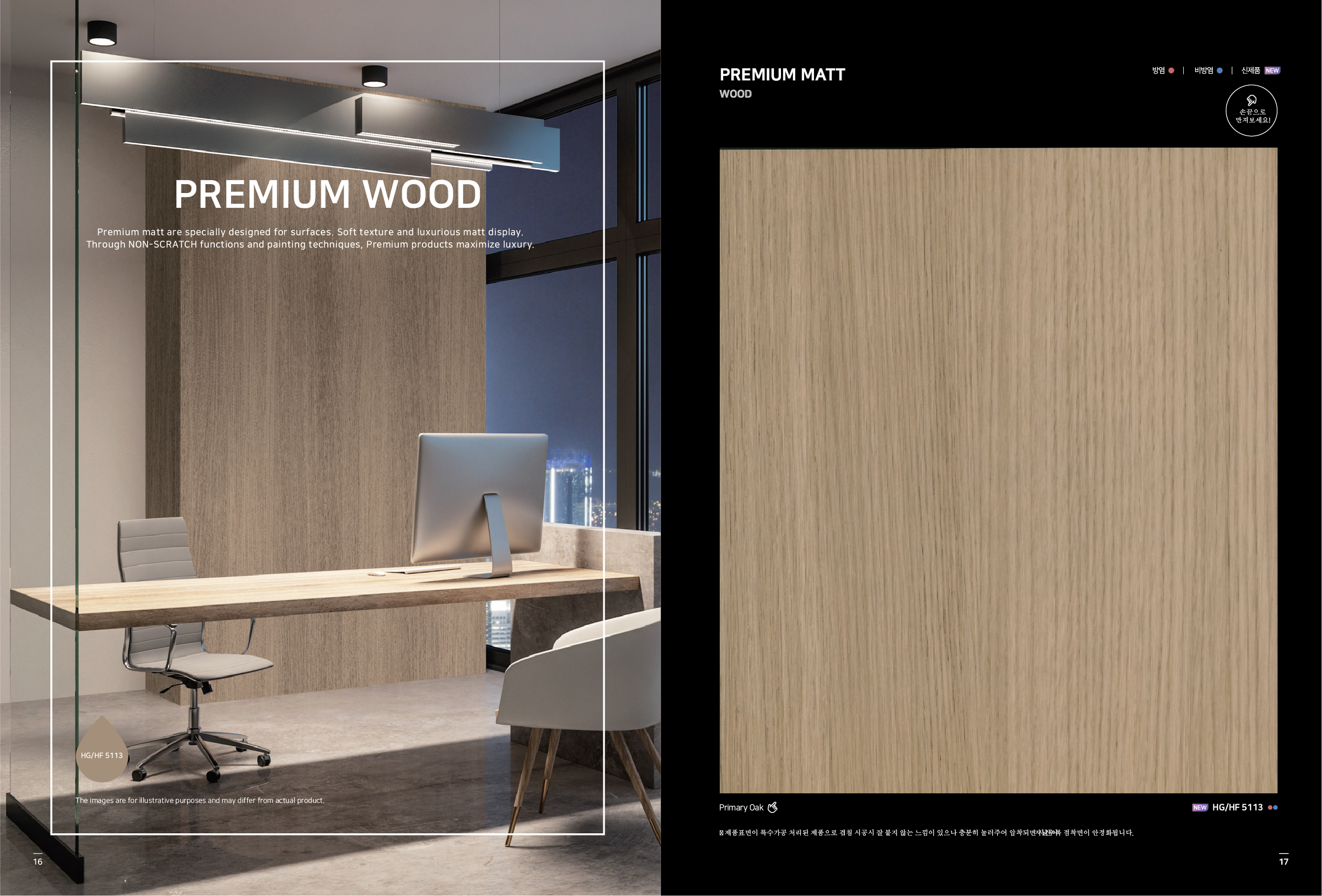

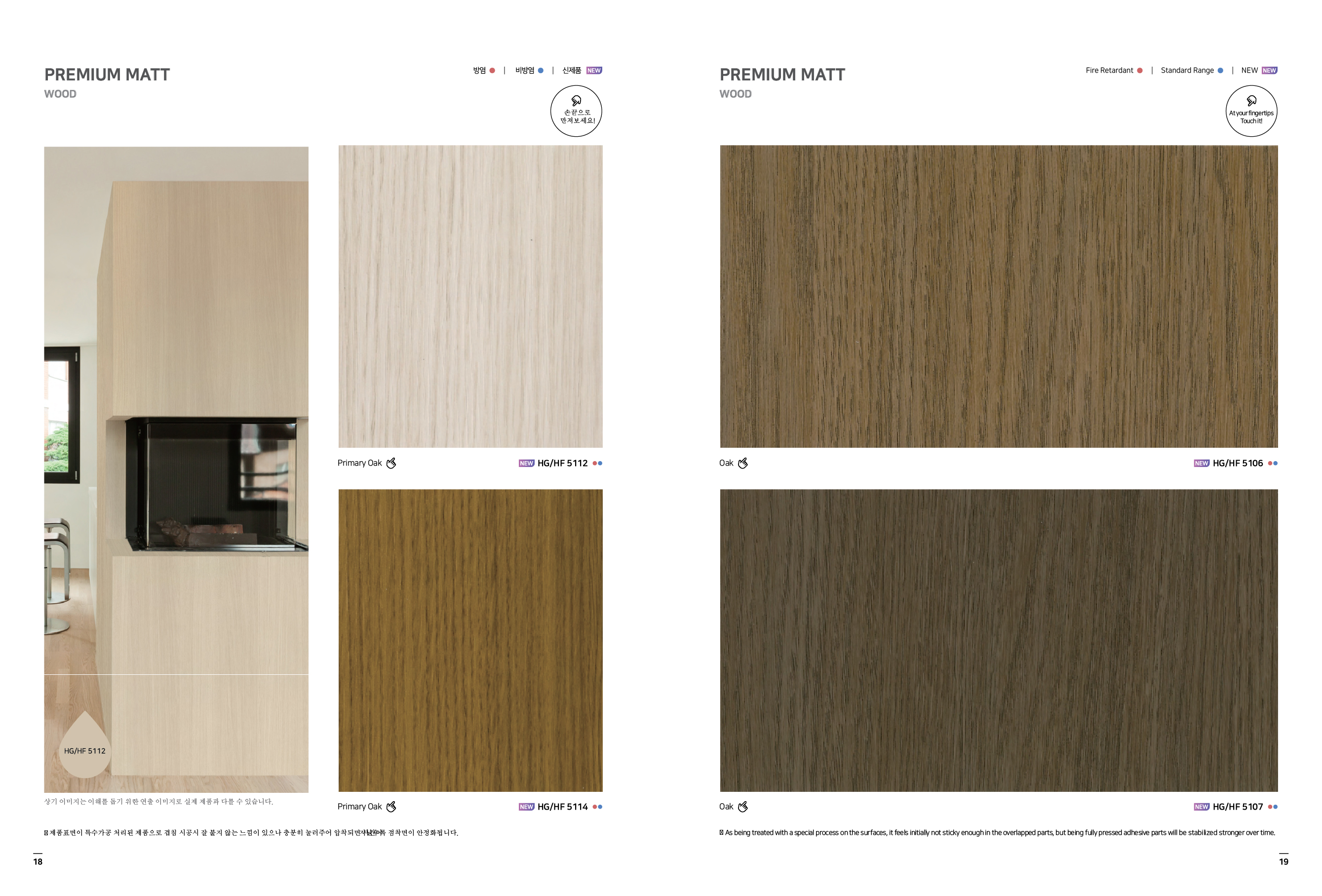

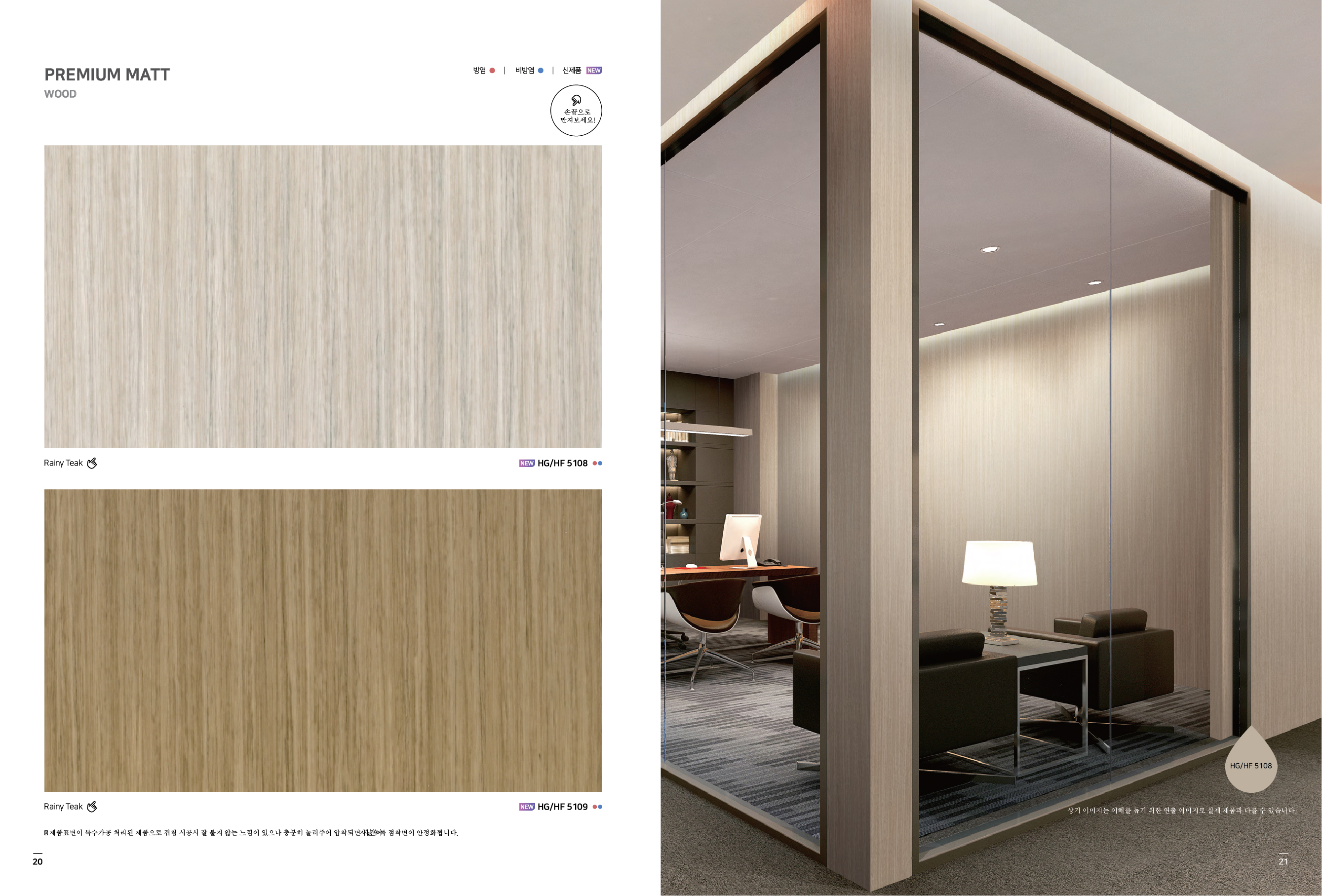

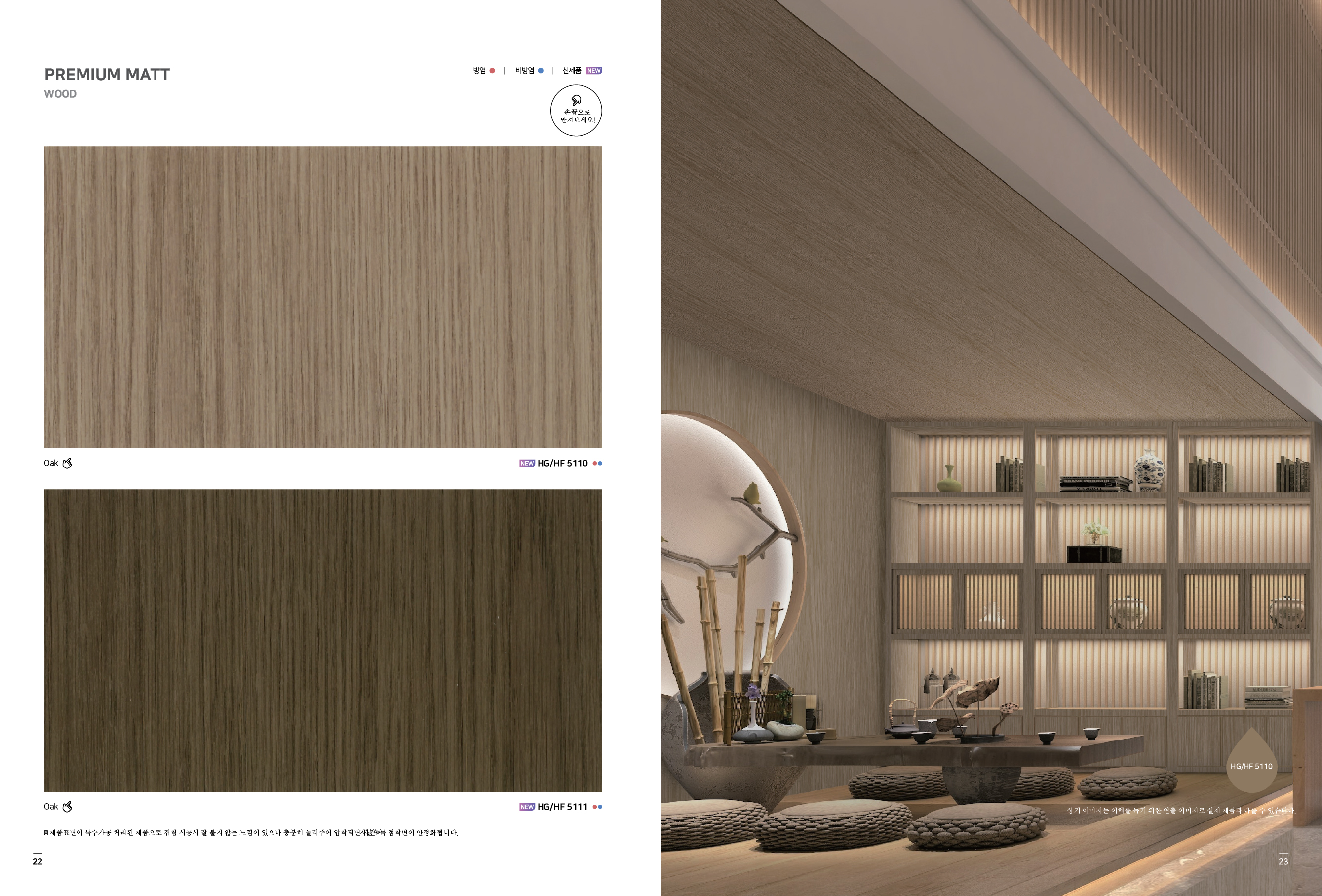

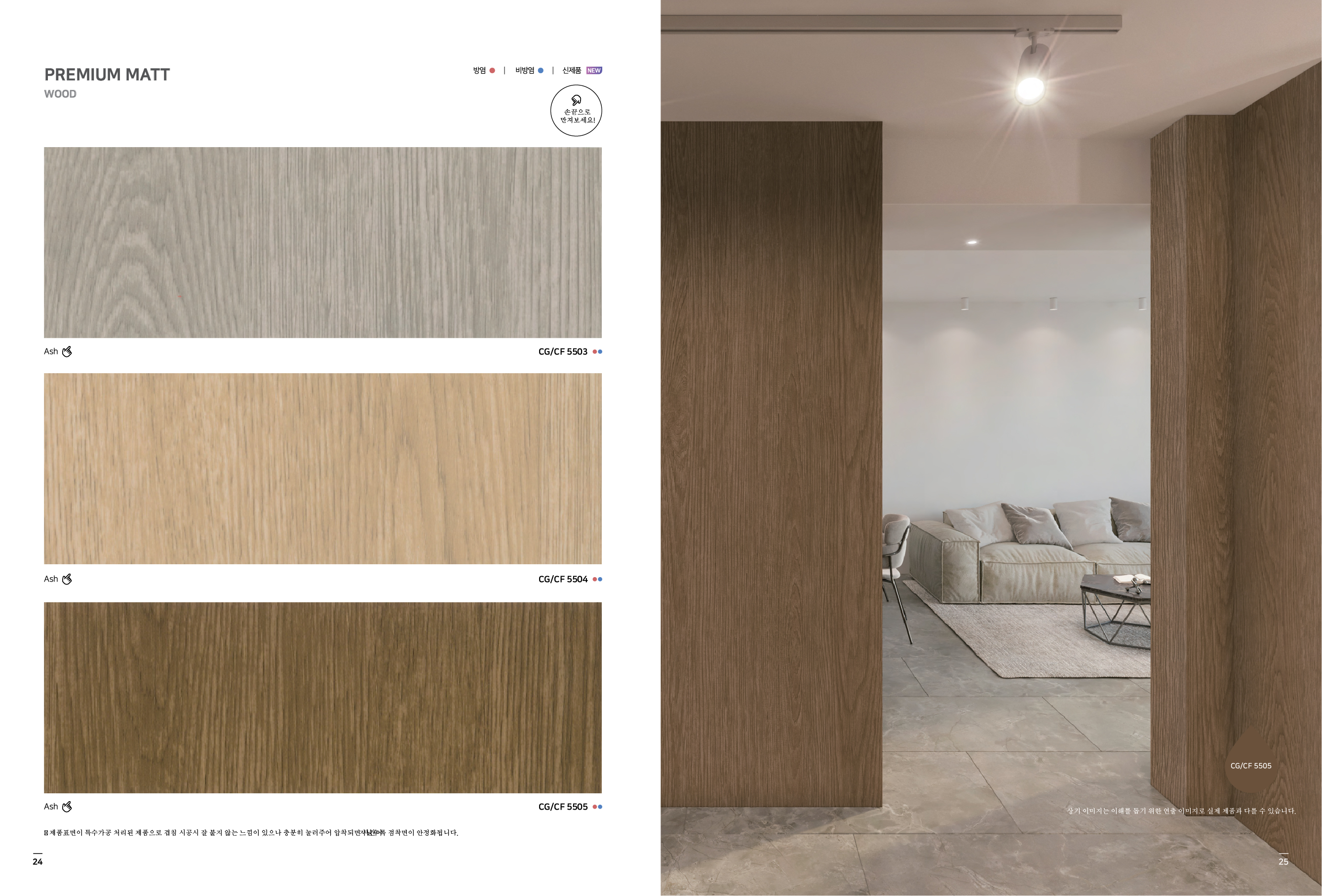

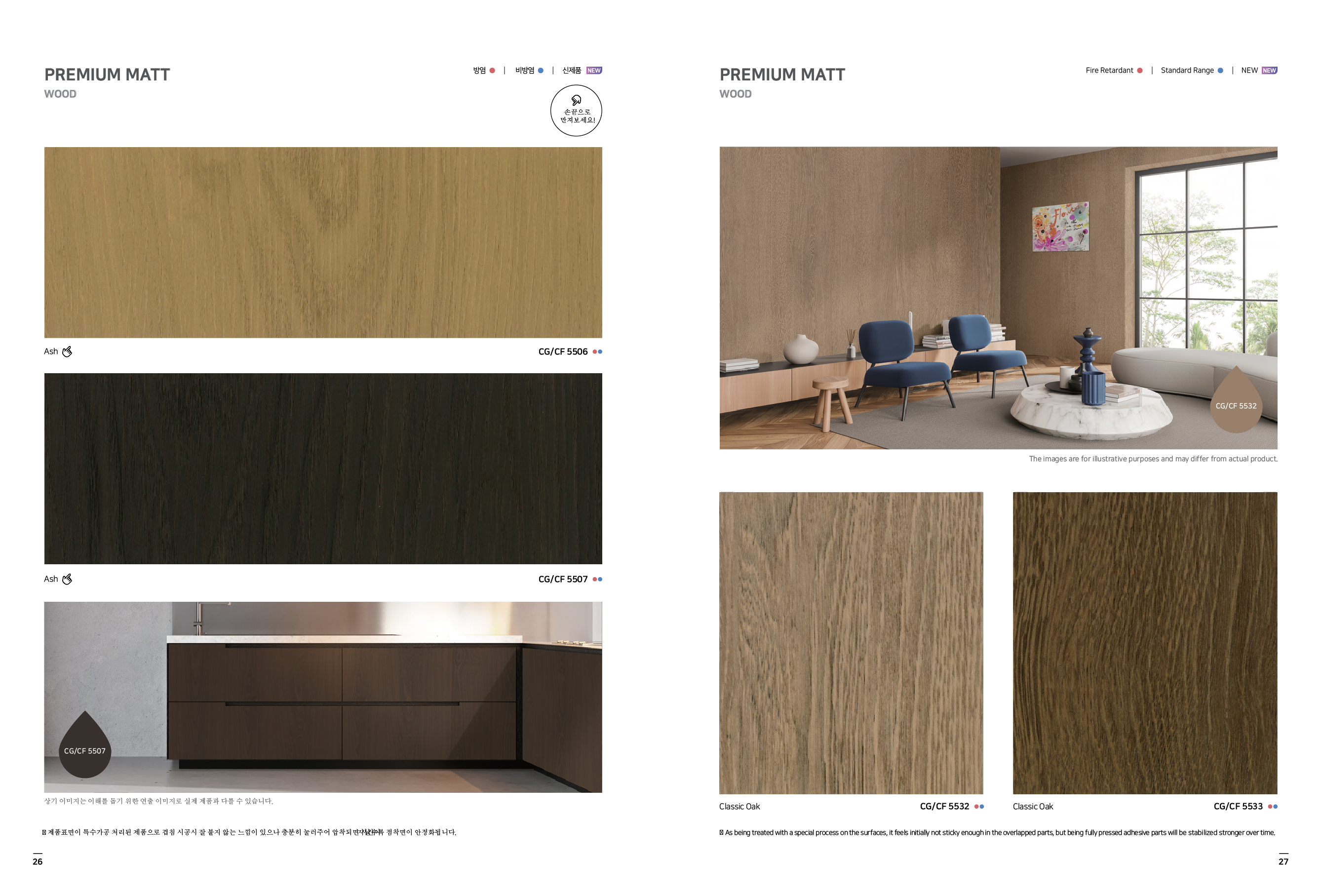

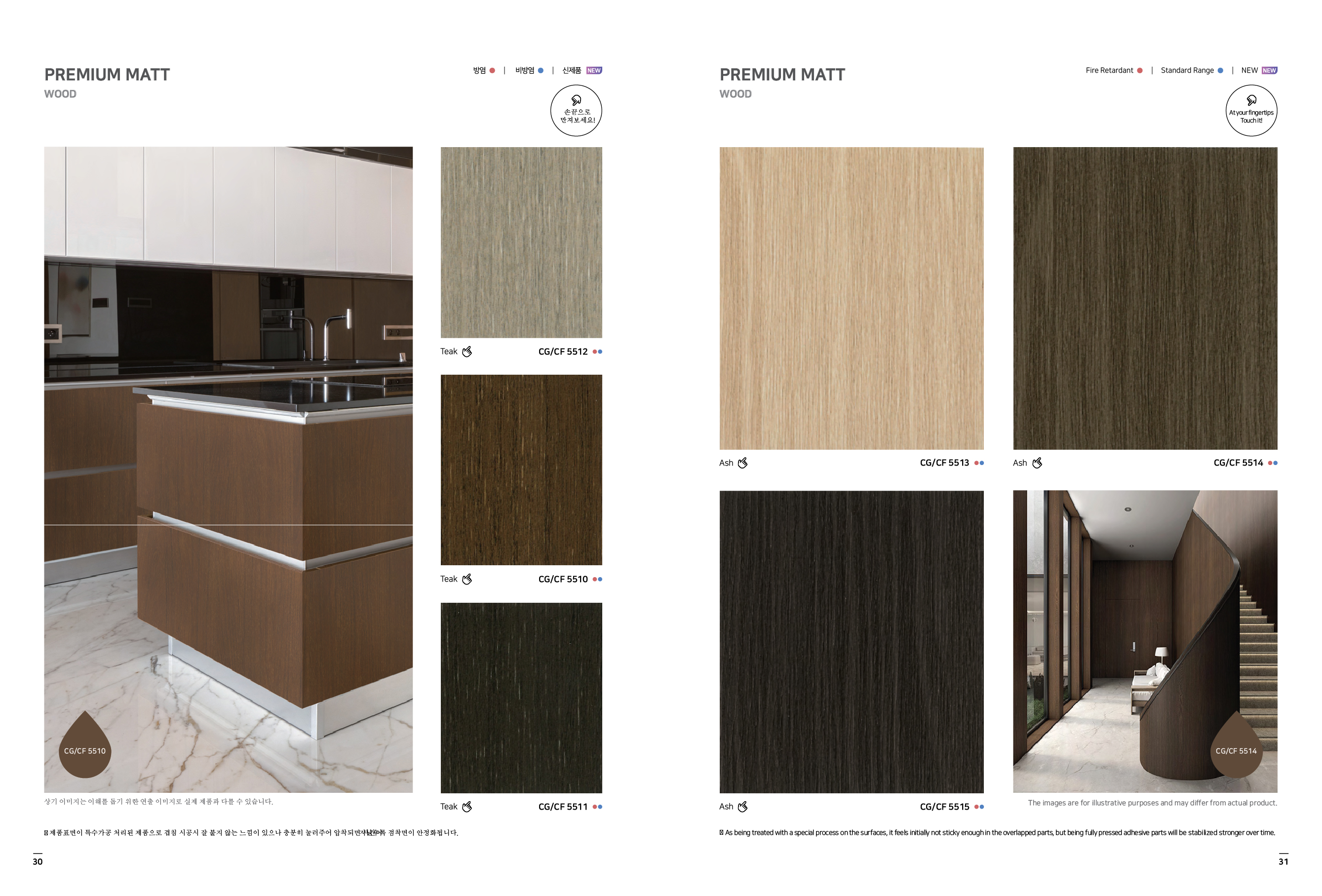

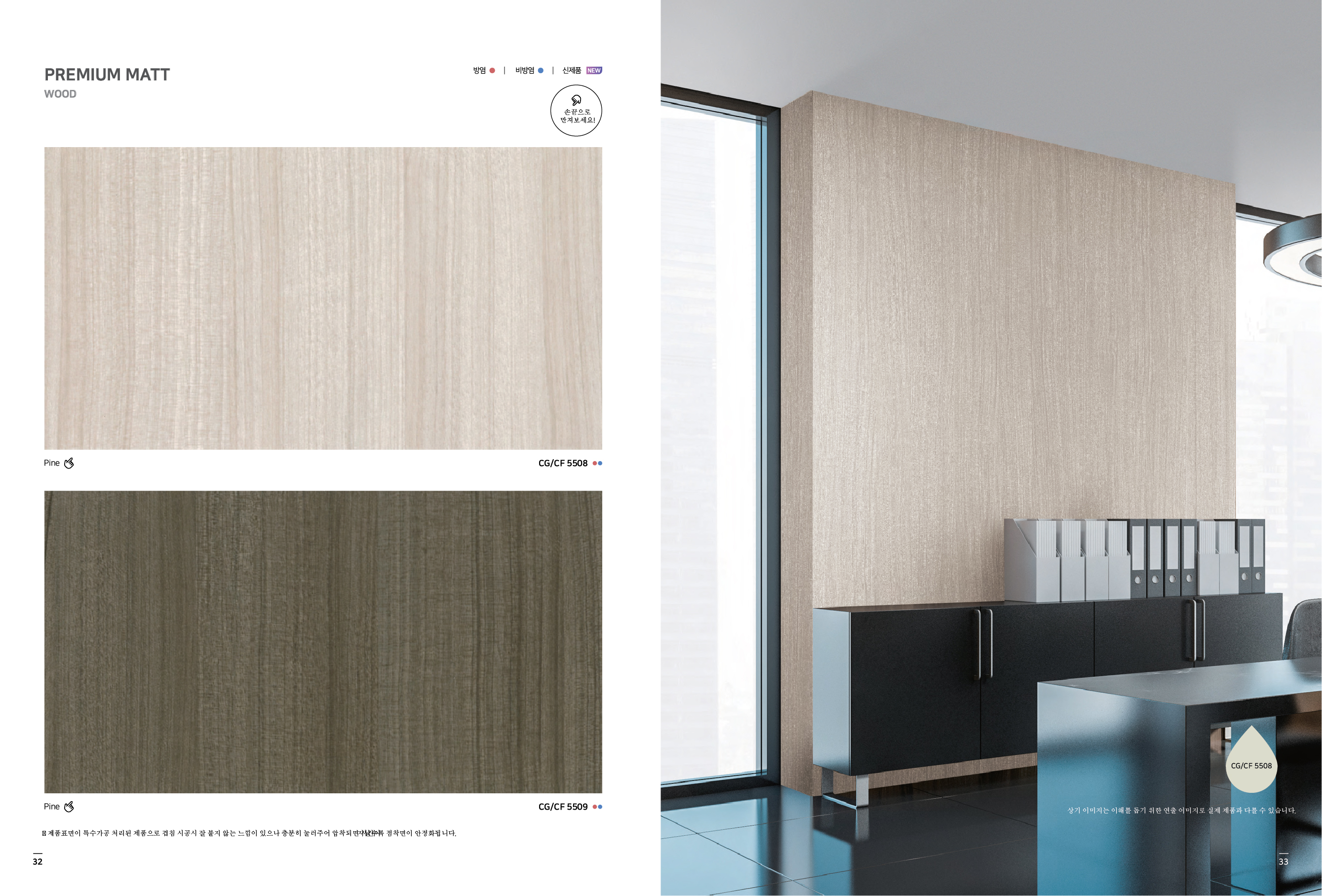

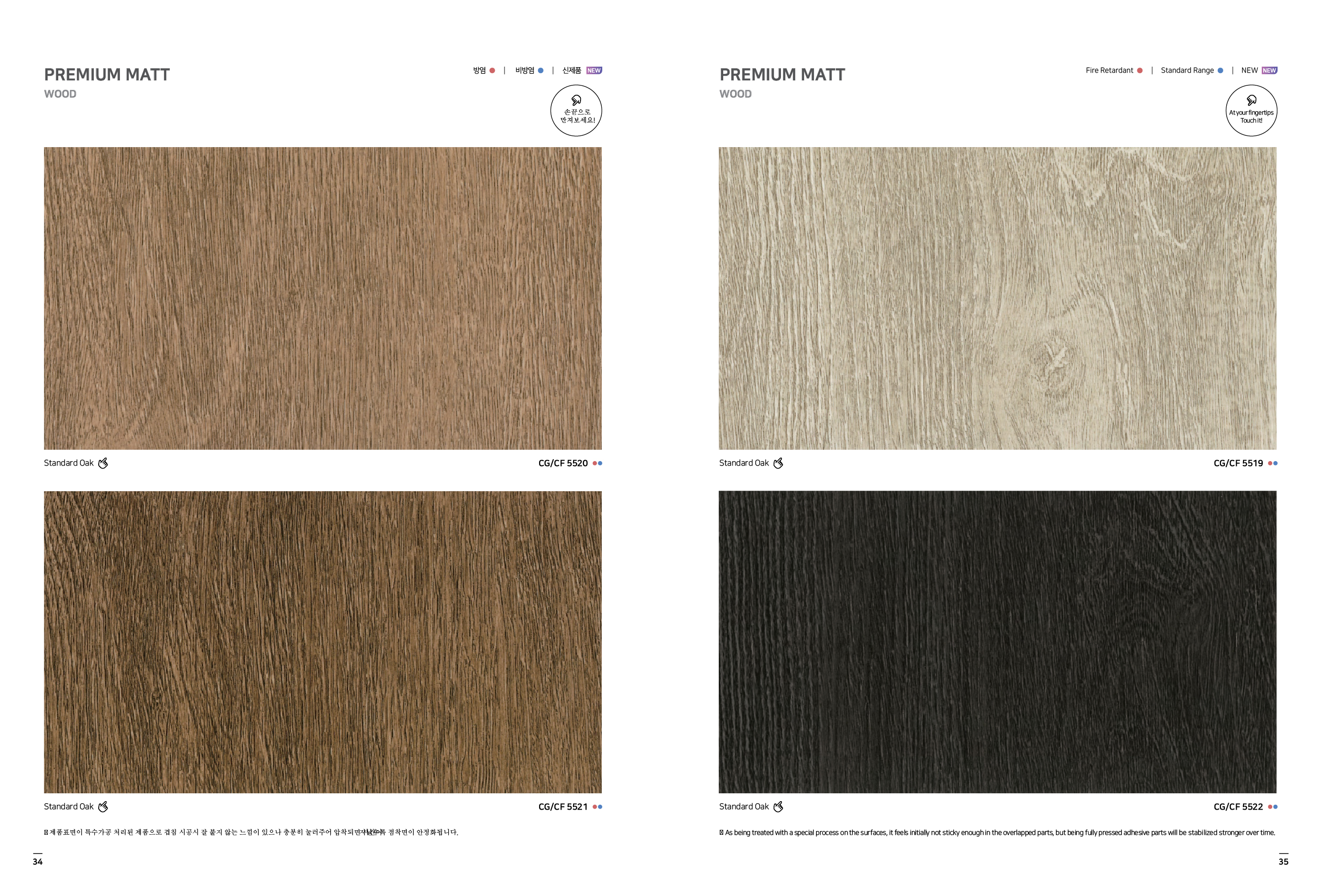

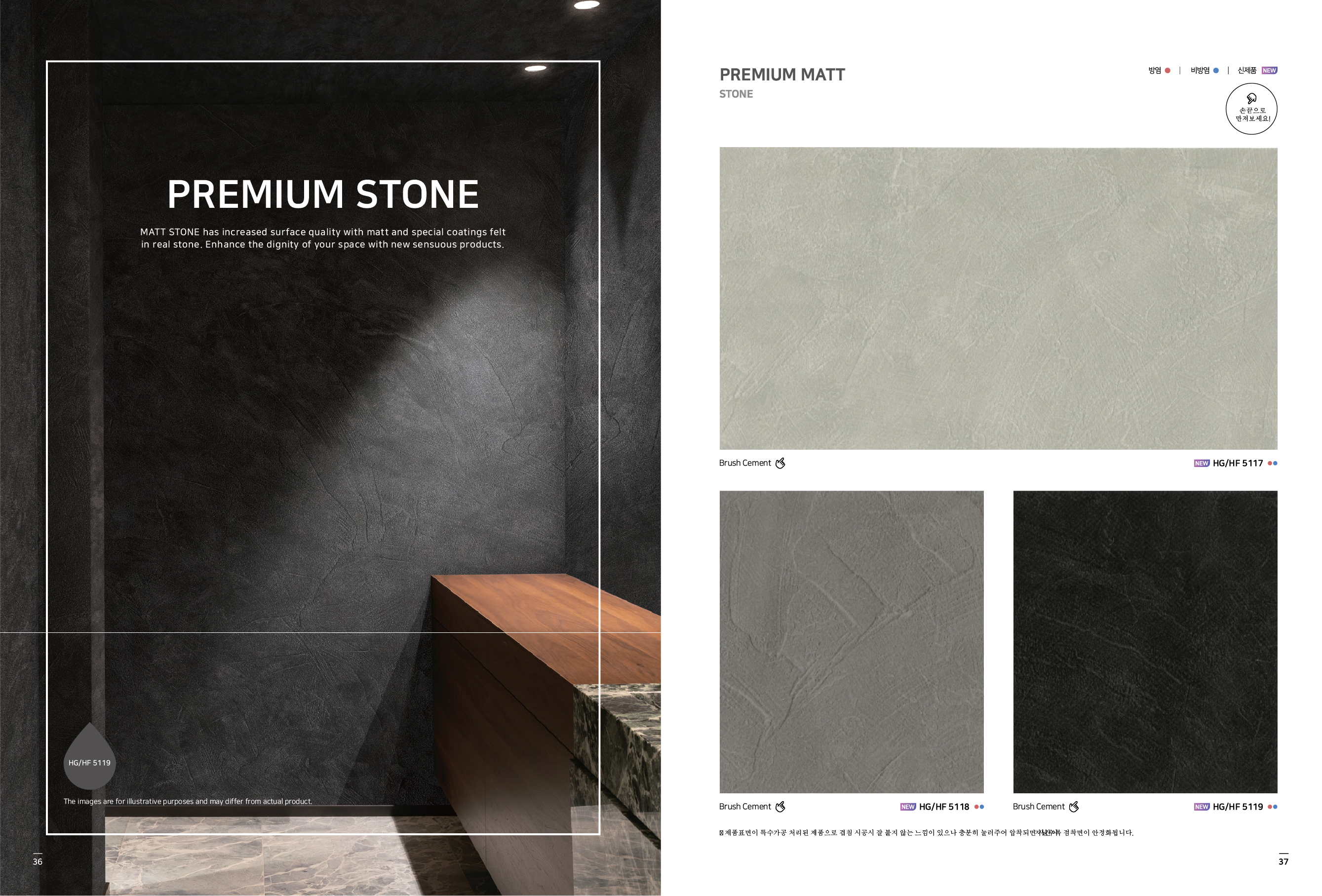

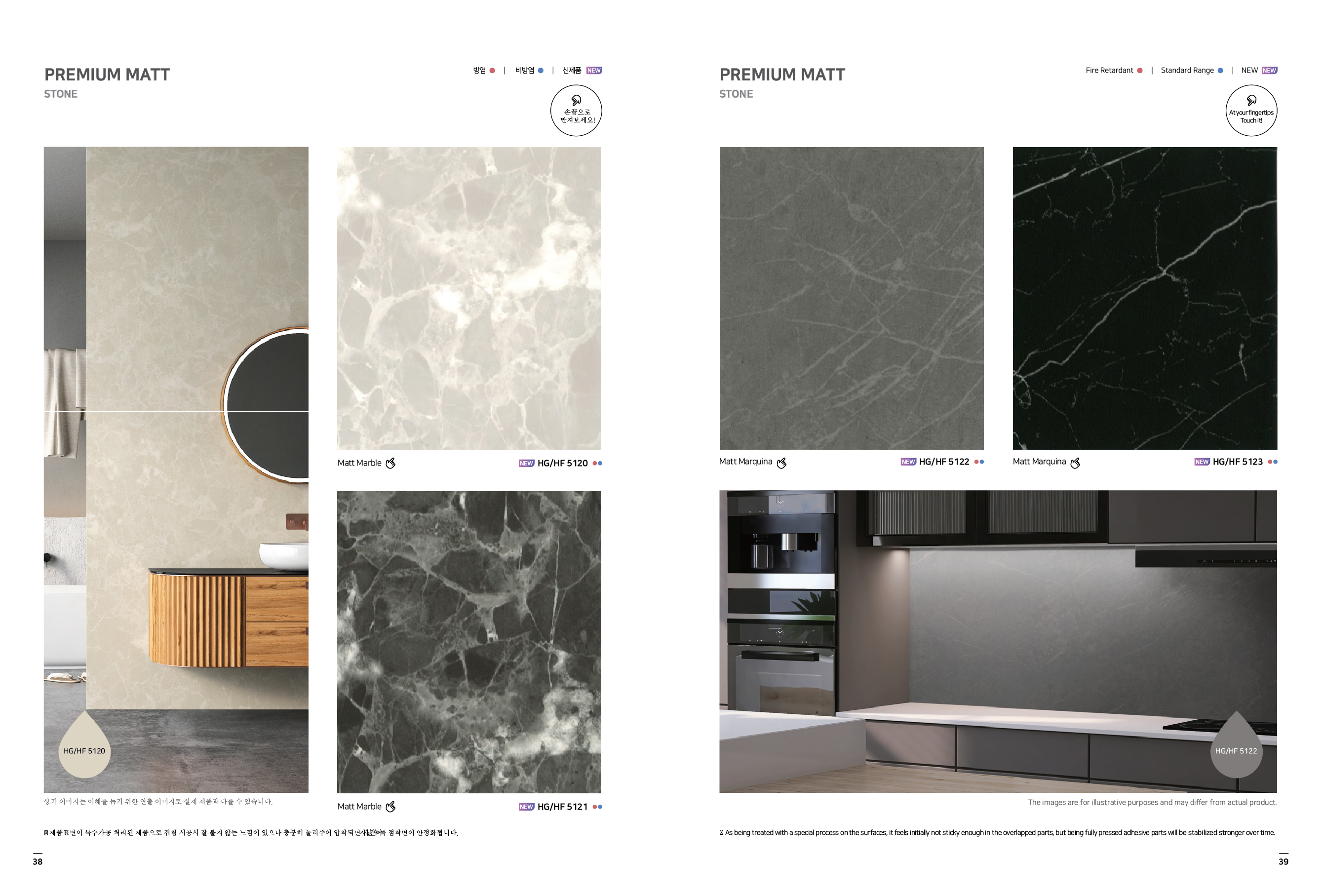

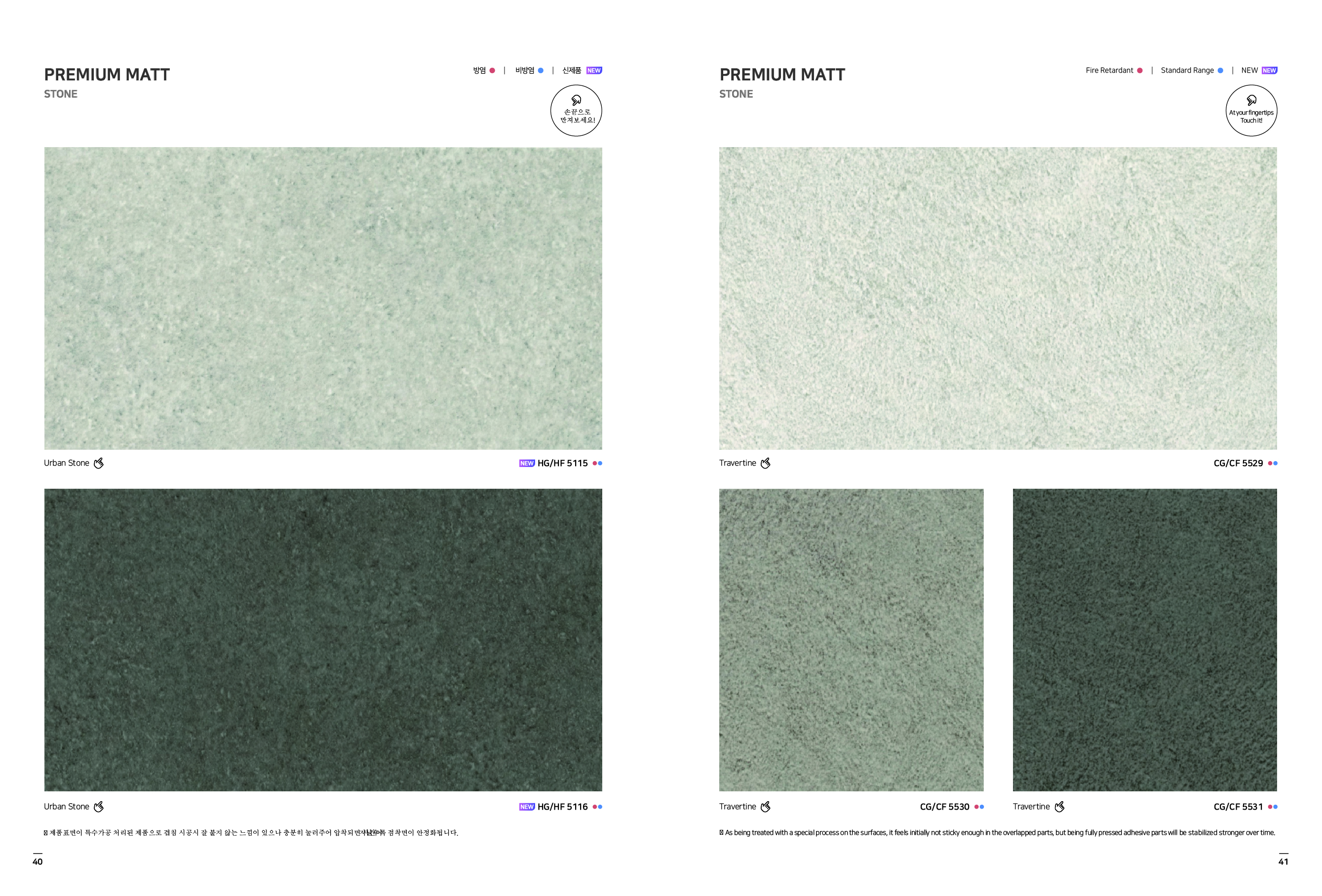

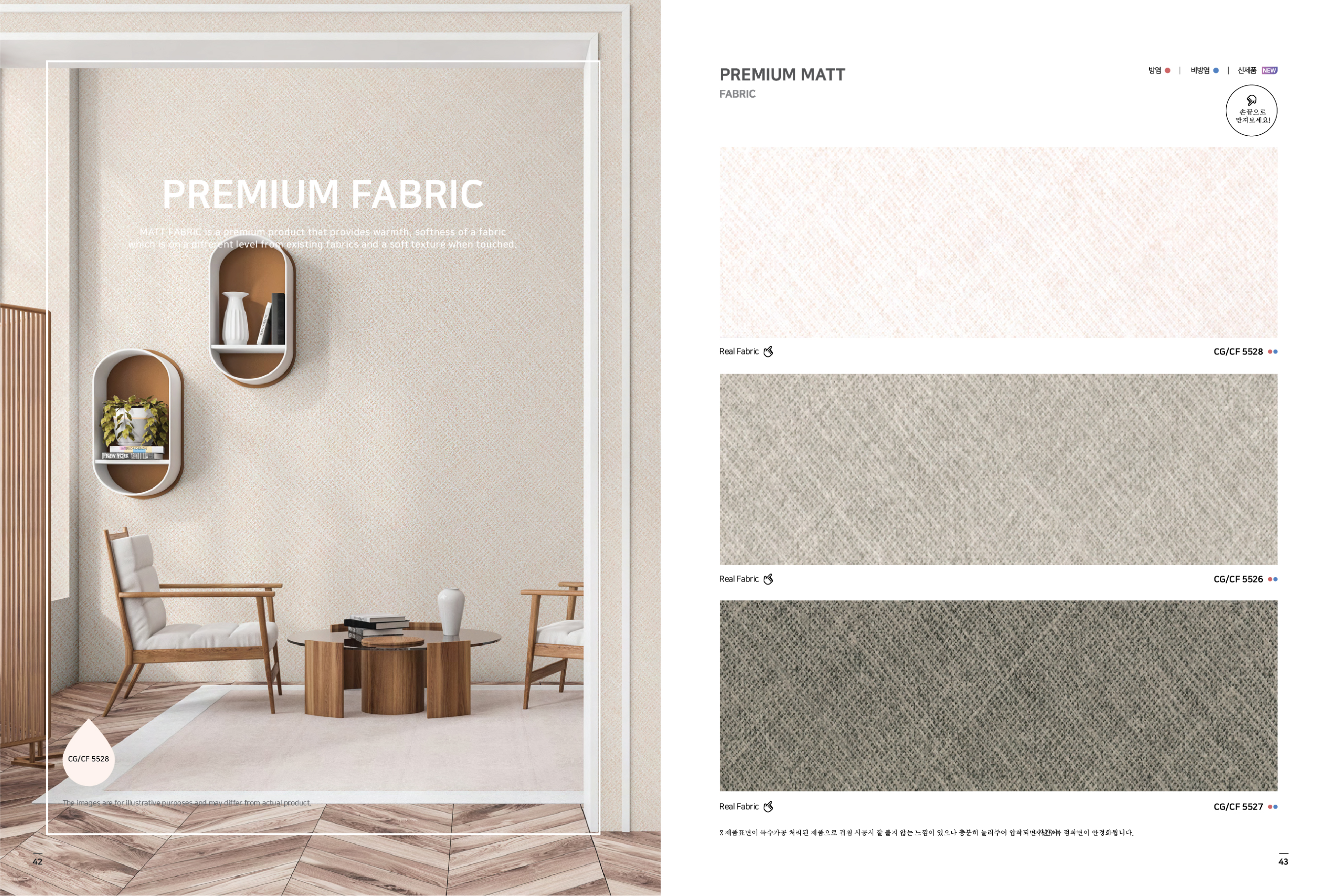

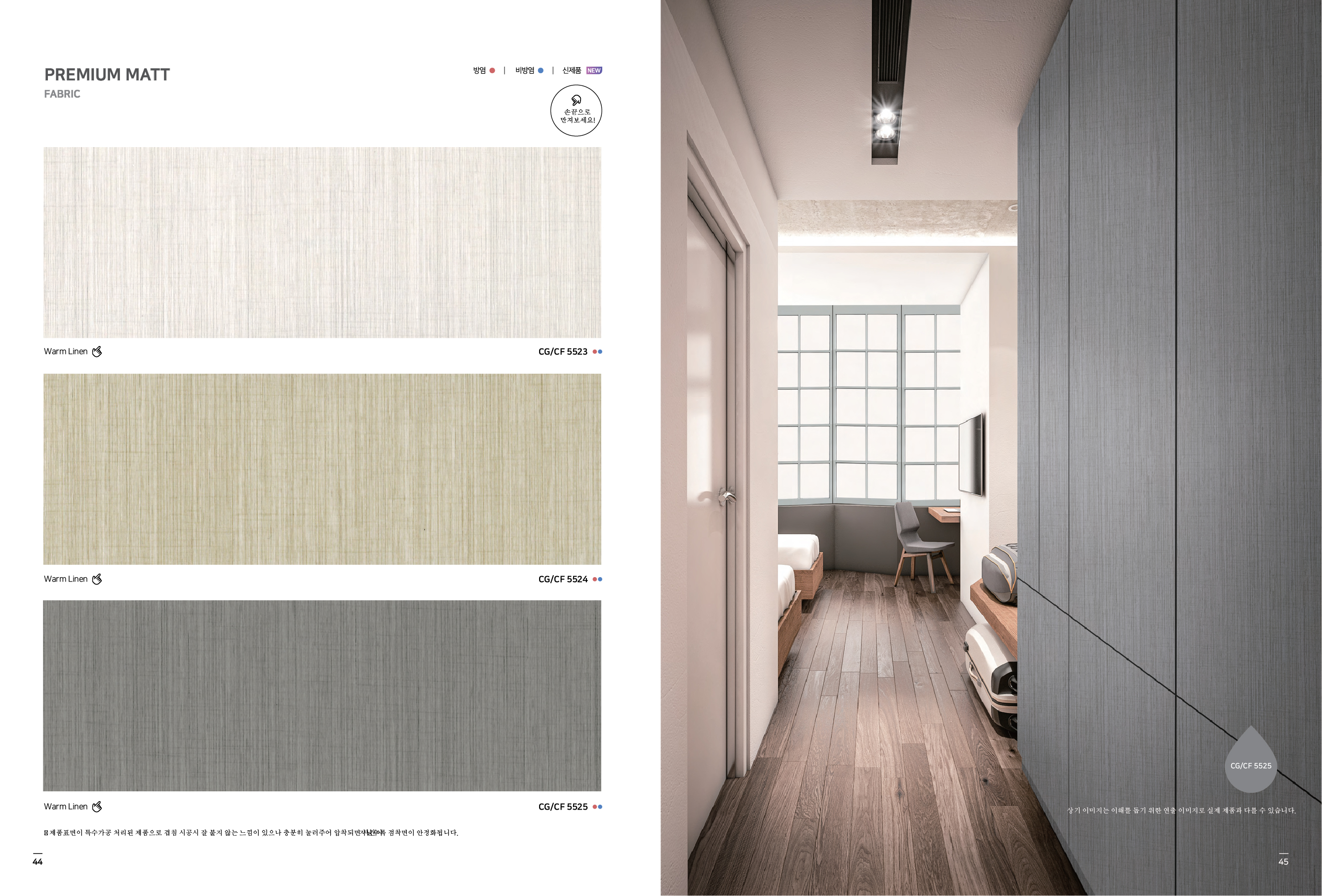

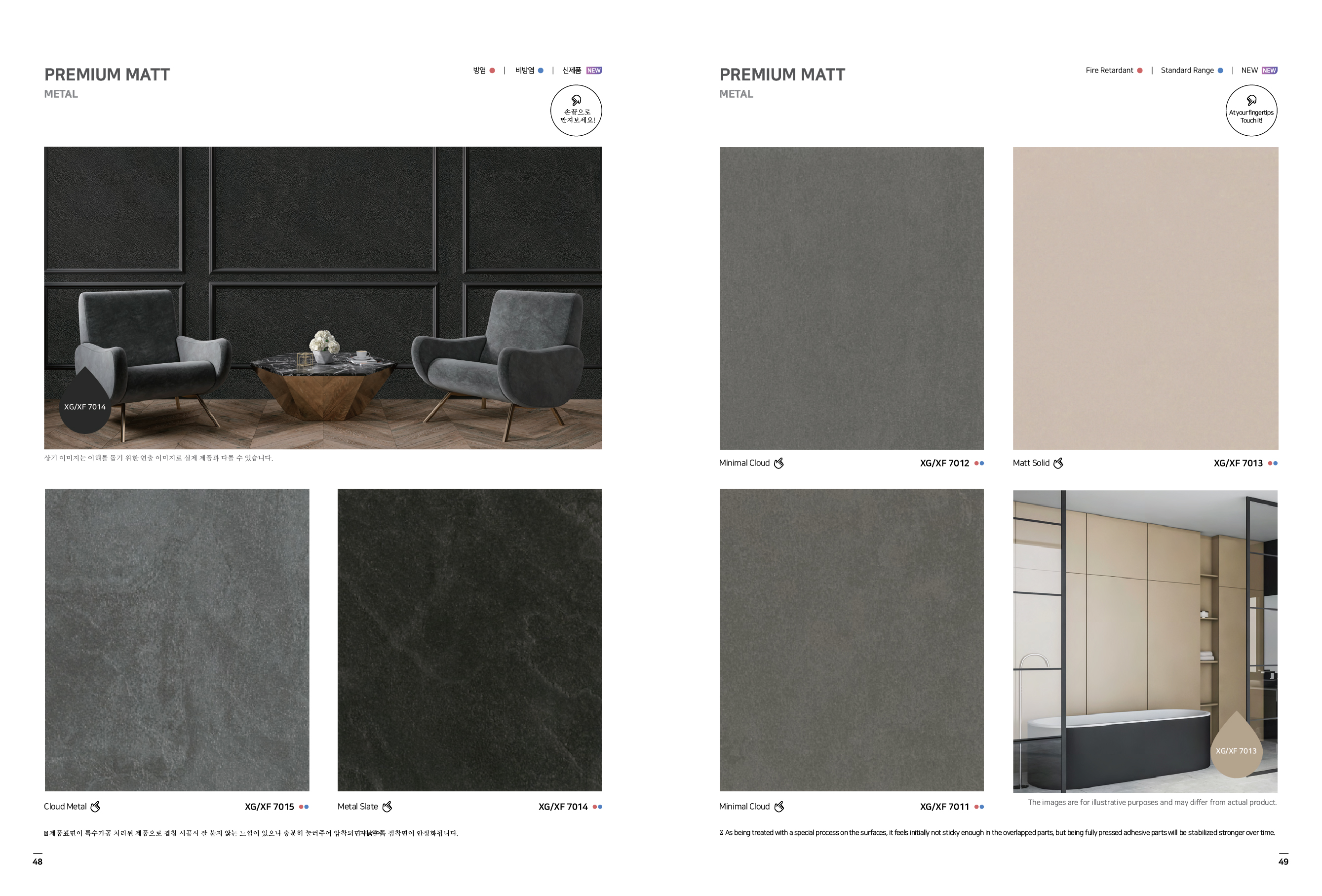

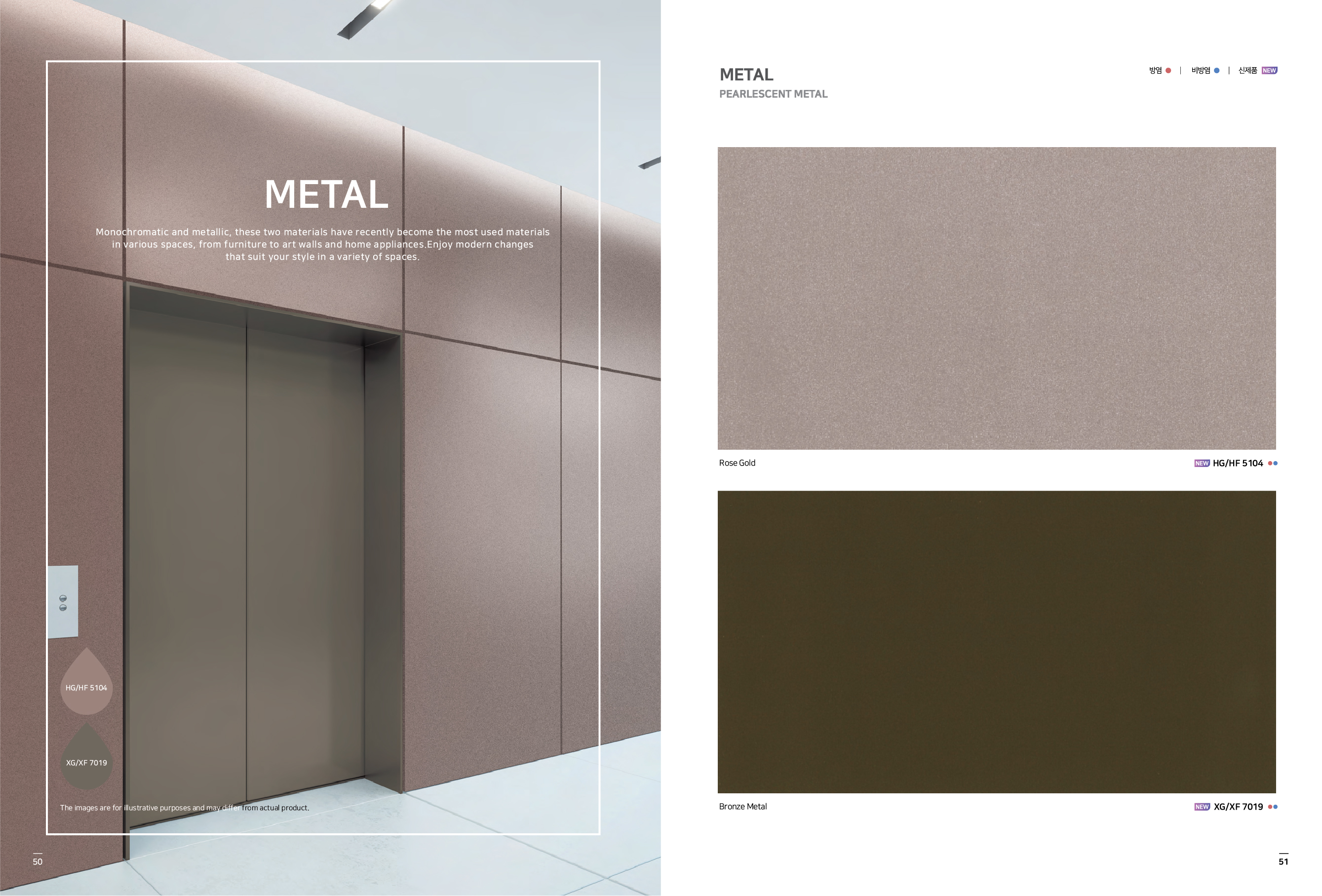

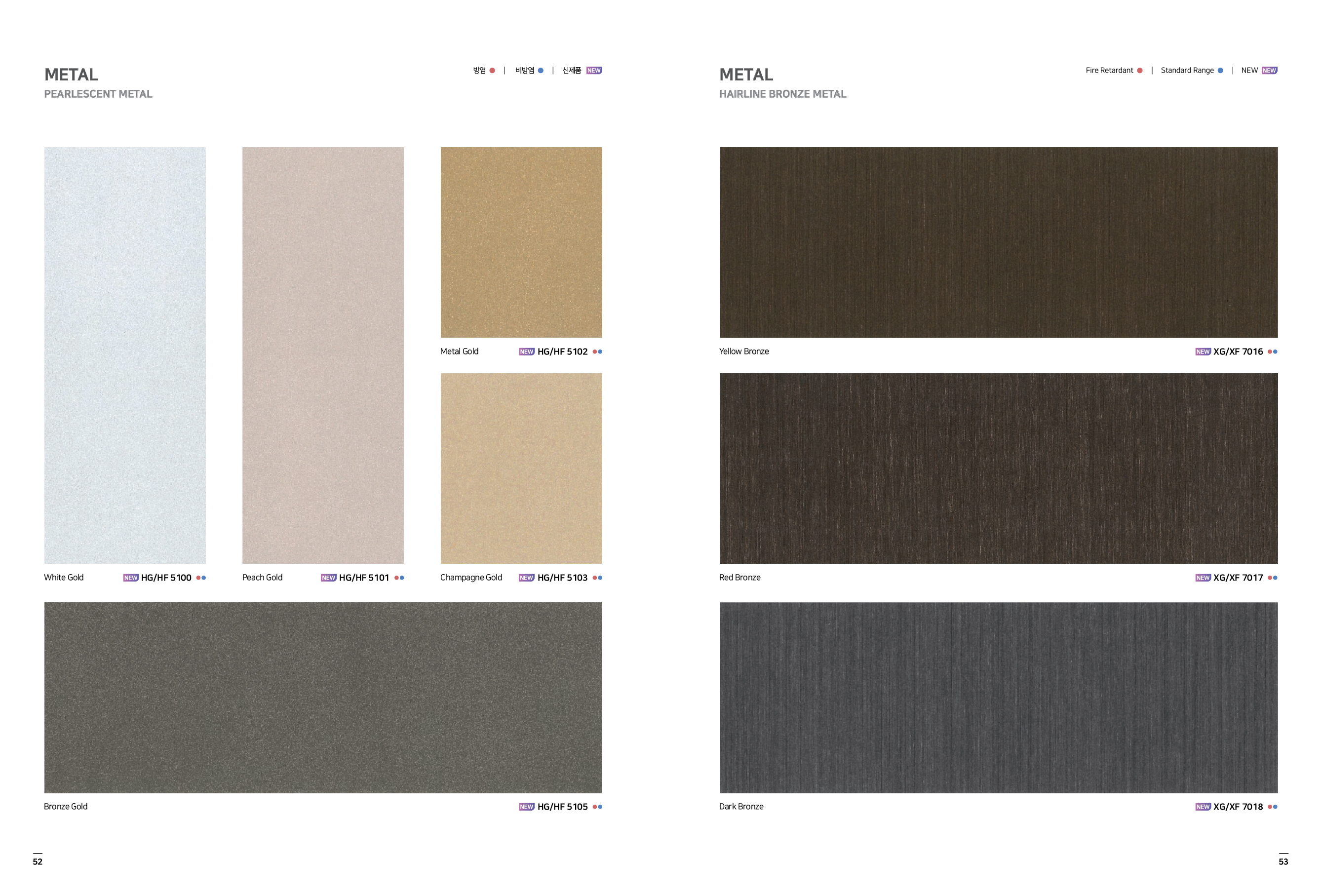

| PREMIUM MATT LINE UPs, SOFT MATT (Soild) | As being treated with a special process on the surfaces, it feels initially not sticky enough in the overlapped parts, but being fully pressed adhesive parts will be stabilized stronger over time. (Method when contaminated: Wipe with an alkaline alcohol to remove.) |

5. Product Storage and Precautions

- Please avoid moisture and direct sunlight, and please do not use it outdoors.

- The surface may become discolored during prolonged exposure to sunlight or ultraviolet light.

- It is recommended that correct storage temperatures are used for storing the product to be free from long term storage defects. (15°C to 25°C)

- When installing the film, please use the manufacturer’s recommended products.

6. Additional Information

- Unauthorized reproduction and use of any content published in this website is prohibited.

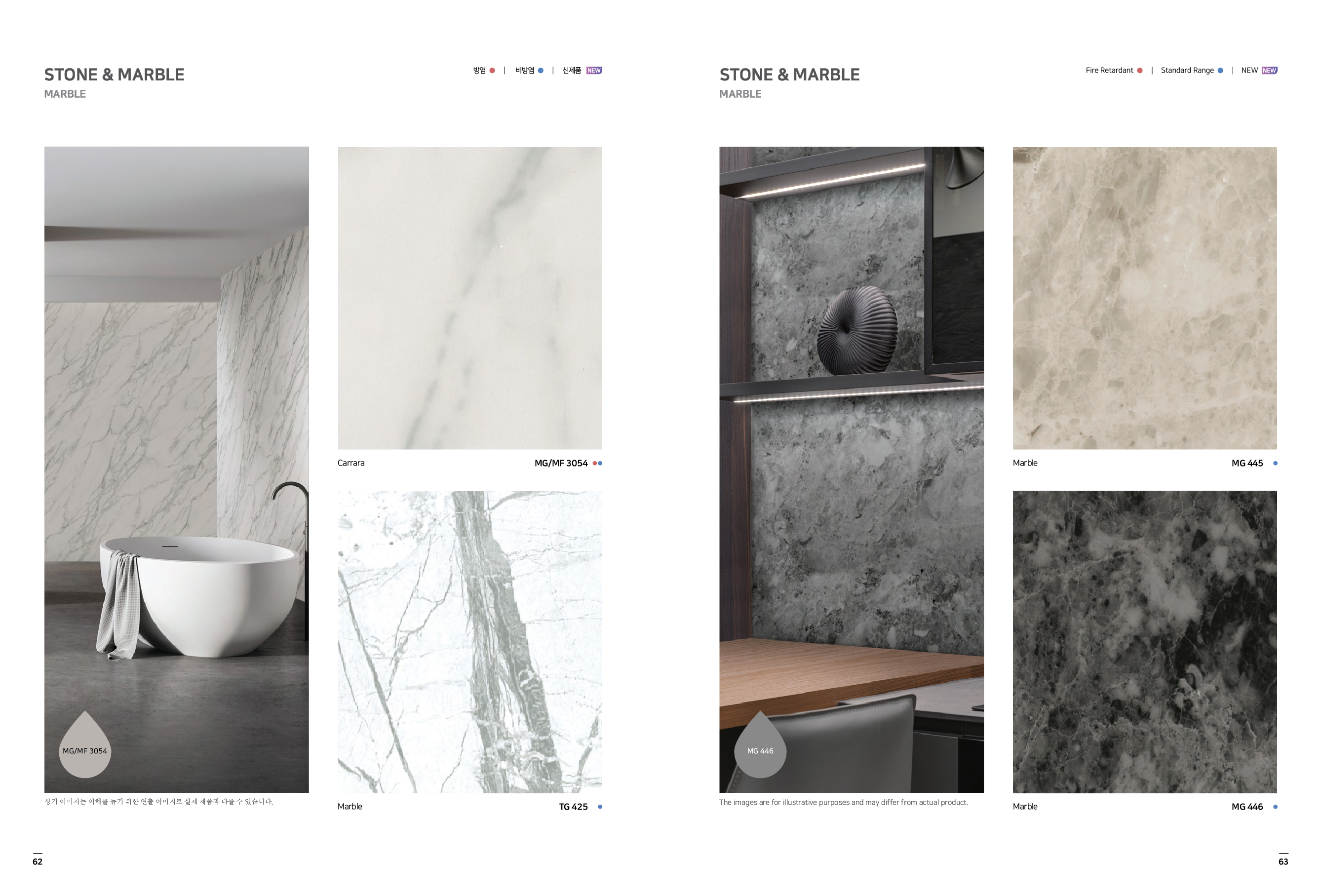

- The colors of the products listed in the sample book may differ from the actual product.

Product Installation

Please refer to "Installation Guide" for additional details.